Wholesale Dealers of Ultrasonic Sonochemistry Machine For Liquid Treatment - ultrasonic grain refinement in aluminium alloys – JH

Wholesale Dealers of Ultrasonic Sonochemistry Machine For Liquid Treatment - ultrasonic grain refinement in aluminium alloys – JH Detail:

DESCRIPTION:

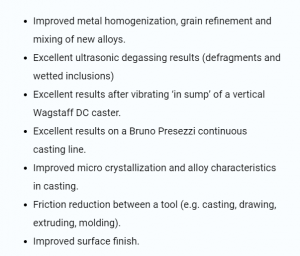

Ultrasonic grain refinement equipment‘s main functions in the process of aluminum melt treatment are: refining metal grains, homogenizing alloy composition, significantly improving the strength and fatigue resistance of casting materials, improving the comprehensive properties of materials, reducing the use of grain refiners and reducing costs.

1. Ultrasonic inclusion removal

It is very difficult for metal solution to float on small inclusions. Only when they gather can they float up. When ultrasonic treatment of aluminum solution, small inclusions can be layered and aggregated. With grain refiner, large particle inclusions float up to remove impurities.

2. Ultrasonic degassing

when the elastic vibration is introduced into the molten metal, cavitation phenomenon is found, which is due to the cavity generated after the continuity of the liquid phase is broken, so the gas dissolved in the liquid metal concentrates to other places. Due to the elastic vibration of ultrasonic, the bubble core is generated and grows continuously until it can be discharged from the molten metal.

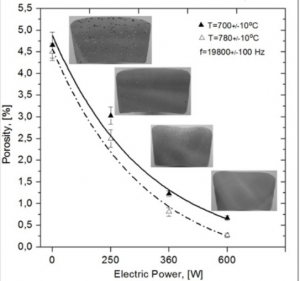

3. Effect of ultrasonic wave on the quality of casting embryo

When the ultrasonic vibration solidification method is used to produce castings, the ultrasonic wave will produce the alternating sound pressure of the banner and form a jet. Due to the nonlinear effect, colleagues will produce sound flow and micro sound flow, while the ultrasonic empty talk will produce a high-speed jet at the interface between solid and liquid. All these effects can cut and destroy dendrites, Wherever there is a sound field inside the liquid, it plays a role. Using the cavitation effect in this process, it can purify the structure, refine the particles and homogenize the structure. In addition to the mechanical effect caused by vibration to destroy the dendrites, another important role of ultrasonic vibration solidification is to improve the effective supercooling of liquid metal. The critical nucleus radius is reduced. Thus, the nucleation rate is increased and the grains are refined.

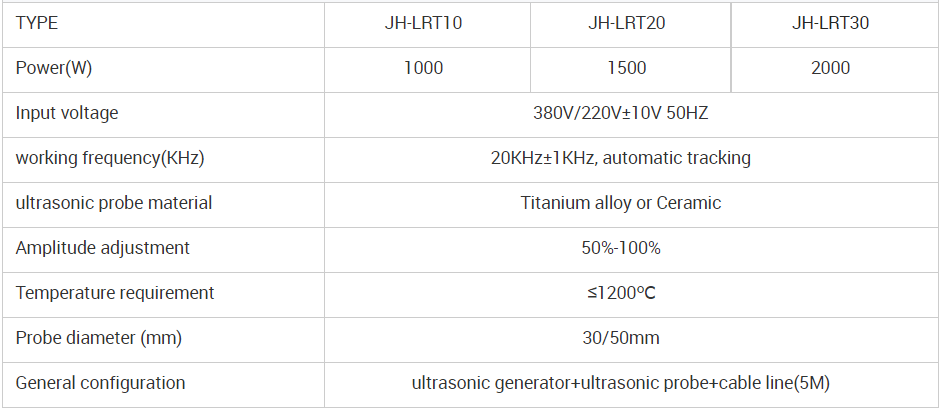

SPECIFICATIONS:

ADVANTAGES:

CASES:

Product detail pictures:

Related Product Guide:

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Wholesale Dealers of Ultrasonic Sonochemistry Machine For Liquid Treatment - ultrasonic grain refinement in aluminium alloys – JH , The product will supply to all over the world, such as: Kuwait, Plymouth, Stuttgart, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.