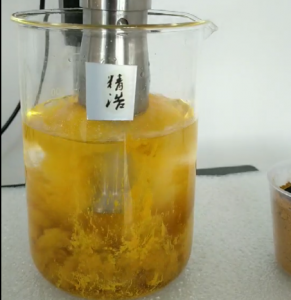

Ultrasonic sonochemistry machine for liquid treatment

ltrasonic sonochemistry is the application of ultrasound to chemical reactions and processes. The mechanism causing sonochemical effects in liquids is the phenomenon of acoustic cavitation.

Acoustic cavitation can be used for various applications such as dispersion, extraction, emulsification, and homogenization. In terms of throughput, we have different equipment to meet the throughput of various specifications: from 100ml to hundreds of tons of industrial production lines per batch.

SPECIFICATIONS:

| MODEL | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

The role of ultrasound in chemical reactions:

increase in reaction speed

increase in reaction output

more efficient energy usage sonochemical methods for switching of reaction pathway

performance improvement of phase transfer catalysts

avoidance of phase transfer catalysts

use of crude or technical reagents

activation of metals and solids

increase in the reactivity of reagents or catalysts