Ultrasonic nanoemulsions production equipment

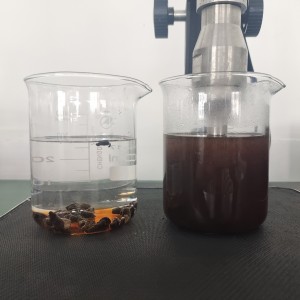

Nanoemulsions ( oil emulsion, Liposome emulsion) is increasingly used in medical and healthcare industries. The huge market demand has promoted the development of efficient nanoemulsion manufacturing technology. Ultrasonic nanoemulsion preparation technology has proved to be the best way at present.

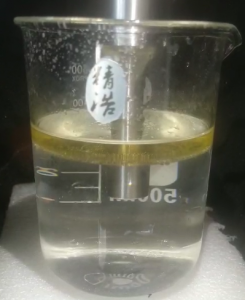

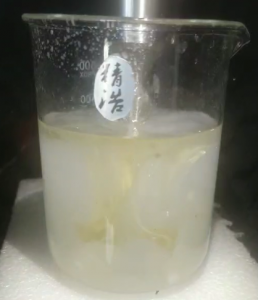

Ultrasonic cavitation produces countless small bubbles. These small bubbles form, grow and burst in several wave bands. This process will produce some extreme local conditions, such as strong shear force and microjet. These forces disperse the original large droplets into nano-liquids, and at the same time disperse them evenly into the solution to form a nano-emulsion.

SPECIFICATIONS:

|

MODEL |

JH-BL5 JH-BL5L |

JH-BL10 JH-BL10L |

JH-BL20 JH-BL20L |

|

Frequency |

20Khz |

20Khz |

20Khz |

|

Power |

1.5Kw |

3.0Kw |

3.0Kw |

|

Input Voltage |

220/110V, 50/60Hz |

||

|

Processing Capacity |

5L |

10L |

20L |

|

Amplitude |

0~80μm |

0~100μm |

0~100μm |

|

Material |

Titanium alloy horn, glass tanks. |

||

|

Pump Power |

0.16Kw |

0.16Kw |

0.55Kw |

|

Pump Speed |

2760rpm |

2760rpm |

2760rpm |

|

Max.Flow Rate |

10L/Min |

10L/Min |

25L/Min |

|

Horses |

0.21Hp |

0.21Hp |

0.7Hp |

|

Chiller |

Can control 10L liquid, from -5~100℃ |

Can control 30L liquid, from -5~100℃ |

|

|

Remarks |

JH-BL5L/10L/20L,match with a chiller. |

||

ADVANTAGES:

1. The nanoemulsion after ultrasonic treatment can be stable for a long time without adding extra emulsifier or surfactant.

2. Nanoemulsion can improve the bioavailability of active compounds.

3. High preparation efficiency, low cost, and environmental protection.