Ultrasonic emulsification equipment for biodiesel

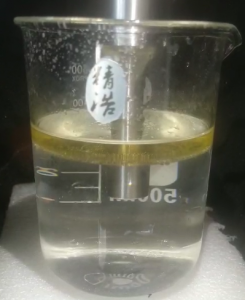

Biodiesel is a mixture of vegetable oils (such as soybeans and sunflower seeds) or animal fats and alcohol. It is actually a transesterification process.

Biodiesel production steps:

1. Mix vegetable oil or animal fat with methanol or ethanol and sodium methoxide or hydroxide.

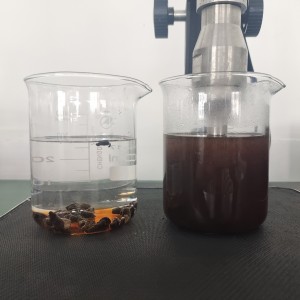

2. Electric heating the mixed liquid to 45 ~ 65 degrees Celsius.

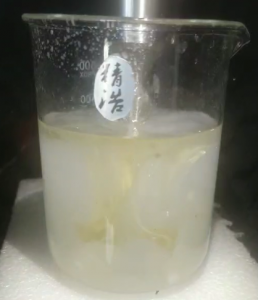

3. Ultrasonic treatment of the heated mixed liquid.

4. Use a centrifuge to separate glycerin to obtain biodiesel.

SPECIFICATIONS:

| MODEL | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

ADVANTAGES:

1. Continuous online production can be achieved to increase output.

2. The processing time is significantly shortened, and the efficiency can be increased by about 400 times.

3. The amount of catalyst is greatly reduced, reducing costs.

4. High oil yield (99% oil yield), good quality of biodiesel.