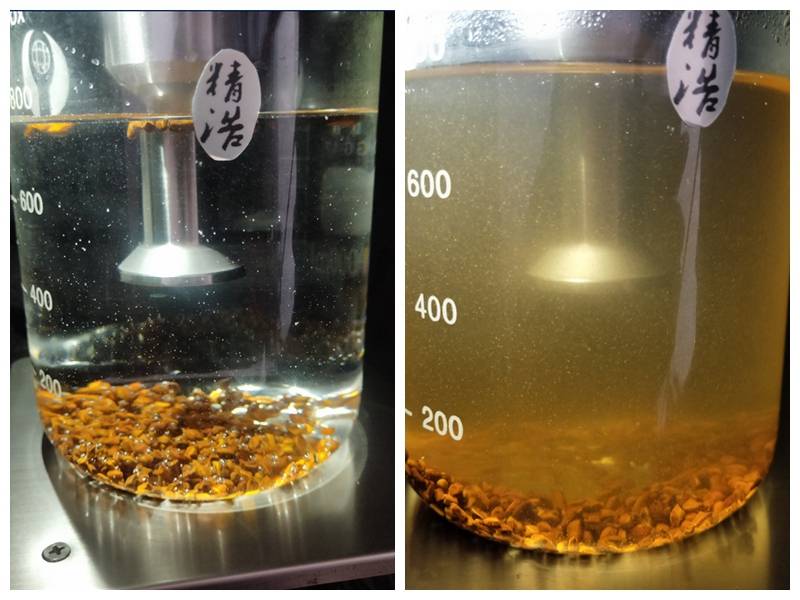

Ultrasonic dispersion processor for nanoparticles

In recent years, nanomaterials have been widely used in various industries to optimize the performance of materials. For example, adding graphene to a lithium battery can greatly extend the service life of the battery, and adding silicon oxide to the glass can increase the transparency and firmness of the glass.

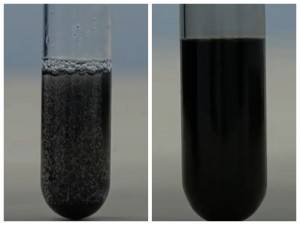

In order to obtain excellent nanoparticles, an effective method is needed.Ultrasonic cavitation instantly forms countless high-pressure and low-pressure areas in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate a strong shear force, deagglomerate and reduce the size of the material.

SPECIFICATIONS:

| MODEL | JH-ZS5JH-ZS5L | JH-ZS10JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

RECOMMENDATIONS:

1.If you are new to nanomaterials and want to understand the effect of ultrasonic dispersion,you can use 1000W/1500W lab ones.

2.If you are a small and medium-sized enterprise, which handles less than 5 tons of liquid per day, you can choose to add an ultrasonic probe to the reaction tank. 3000W probe can be used.

3.If you are a large-scale enterprise, processing dozens of tons or even hundreds of tons of liquids per day, you need an external ultrasonic circulation system, and multiple groups of ultrasonic equipment can simultaneously process the circulation to achieve the desired effect.