Ultrasonic dispersion equipment

Industrial applications often mix different liquids or solids and liquids to formulate various products. Such as: liquid drinks / medicines, paints, coatings, detergents, etc.

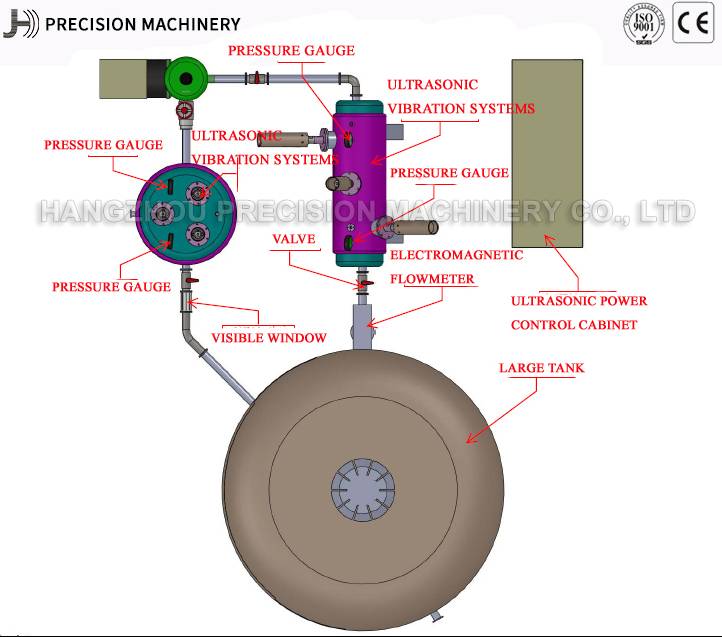

In order to better mix various substances into the solution, it is necessary to disperse the originally agglomerated substances into a single dispersion. Ultrasonic cavitation instantly forms countless high-pressure and low-pressure areas in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate a strong shear force and deagglomerate the material.

SPECIFICATIONS:

| MODEL | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

ADVANTAGES:

- The dispersion efficiency is high, and the efficiency can be increased by more than 200 times in suitable fields.

- The dispersed particles are finer, with better uniformity and stability.

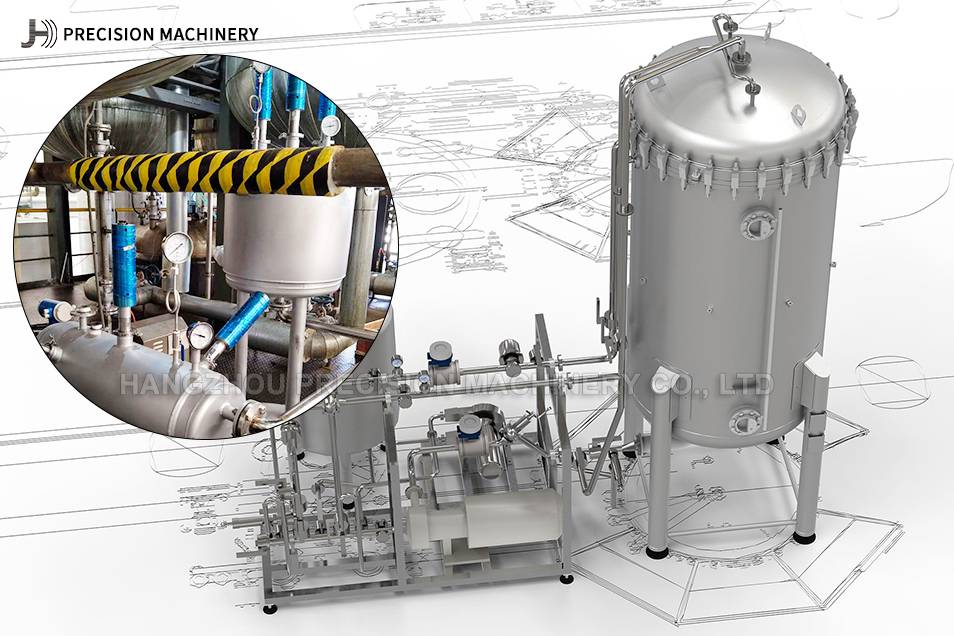

- It is usually installed with a snap flange, which is convenient for moving and cleaning.

Write your message here and send it to us