Top Suppliers 2000w Ultrasonic Homogenizer Make Graphene - ultrasonic graphene dispersion equipment – JH

Top Suppliers 2000w Ultrasonic Homogenizer Make Graphene - ultrasonic graphene dispersion equipment – JH Detail:

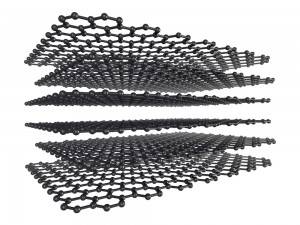

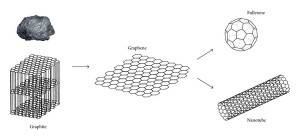

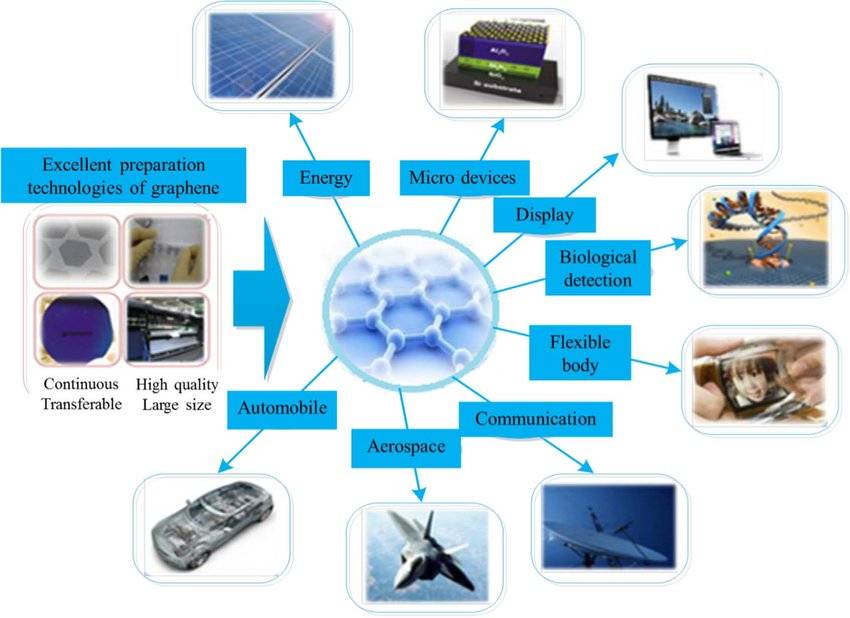

Graphene has excellent material properties, such as enhancing the strength of composite materials, and is increasingly used in the field of composite materials. However, it is difficult to peel off a single layer or a few layers of graphene from graphite. The traditional redox method requires very strong oxidants and reducing agents. The graphene obtained in this case often has defects.

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

SPECIFICATIONS:

| Model | JH-ZS5JH-ZS5L | JH-ZS10JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

ADVANTAGES:

High dispersion efficiency

The dispersed particles are finer and more uniform

Graphene is highly stable

Energy saving and environmental protection

APPLICATIONS:

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Top Suppliers 2000w Ultrasonic Homogenizer Make Graphene - ultrasonic graphene dispersion equipment – JH , The product will supply to all over the world, such as: Angola, Morocco, Algeria, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

xy.jpg)