Reasonable price Industry Dairy Perfume Ultrasonic Dispersion - ultrasonic carbon nanotubes dispersion machine – JH

Reasonable price Industry Dairy Perfume Ultrasonic Dispersion - ultrasonic carbon nanotubes dispersion machine – JH Detail:

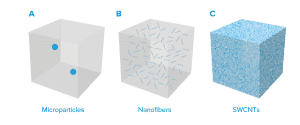

Carbon nanotubes have many uses, and can be used in adhesives, coatings, polymers and as conductive fillers in plastics. By using carbon nanotubes, the polymer’s high temperature resistance, corrosion resistance, pressure resistance and wear resistance have been significantly improved.

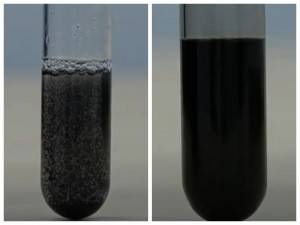

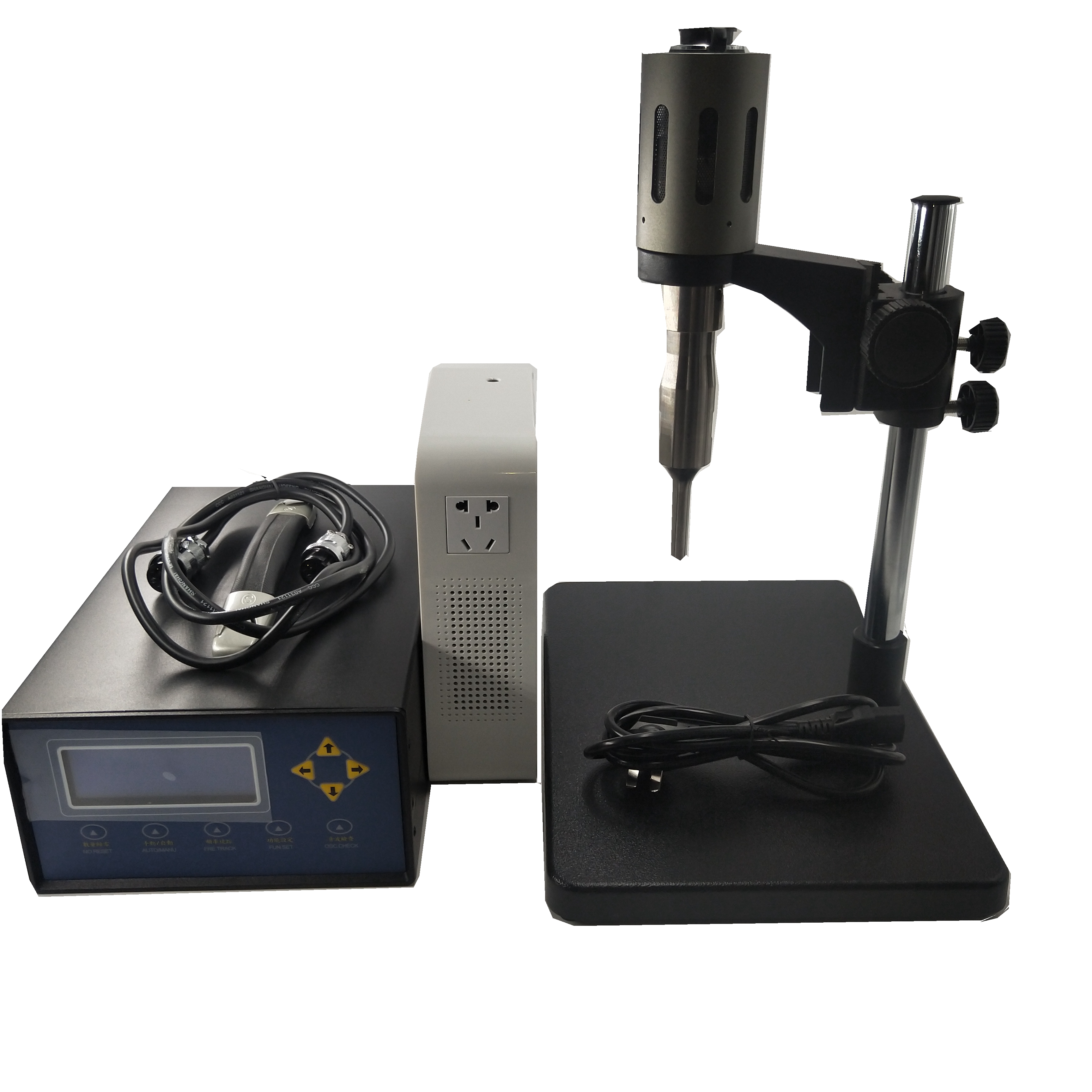

Ultrasonic waves generate powerful shearing forces through 20,000 vibrations per second. The bonding force between carbon nanotubes can be overcome, and the tubes are separated evenly. Generally, the crude nanotube dispersion is pre-mixed by mechanical stirring, and then further dispersed into small beams or single carbon nanotubes using ultrasonic waves. It is recommended to use pipeline ultrasonic equipment.

SPECIFICATIONS:

| Model | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1.Compared with the dispersion in the traditional harsh environment, ultrasonic dispersion can reduce the damage to the structure of single-walled carbon nanotubes and maintain a long single-walled carbon nanotube.

2.It can be completely and evenly dispersed to better achieve the performance of carbon nanotubes.

3.It can quickly disperse carbon nanotubes, avoid degradation of carbon nanotubes, and obtain high concentration carbon nanotube solutions.

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for Reasonable price Industry Dairy Perfume Ultrasonic Dispersion - ultrasonic carbon nanotubes dispersion machine – JH , The product will supply to all over the world, such as: Sevilla, venezuela, Malaysia, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!