PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic silica dispersion equipment – JH

PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic silica dispersion equipment – JH Detail:

Silica is a versatile ceramic material. It has electrical insulation, high thermal stability, and wear resistance. It can improve the performance of various materials. For example: Adding silica to the coating can significantly improve the abrasion resistance of the coating.

Ultrasonic cavitation produces countless small bubbles. These small bubbles form, grow and burst in several wave bands. This process will produce some extreme local conditions, such as strong shear force and microjet. These forces disperse the original large droplets into nano-particles.In this case, silica can be uniformly and effectively dispersed into various materials to play a unique role.

SPECIFICATIONS:

| MODEL | JH-ZS5JH-ZS5L | JH-ZS10JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

WHY CHOOSE US?

- We have more than 5 years of experience in silica dispersion. Pre-sales we can give you many professional suggestions to ensure that you can buy the most suitable products.

- Our equipment has stable quality and good processing effect.

- We have an English-speaking after-sales service team. After receiving the product, you will have a professional installation and use instruction video.

- We provide a 2-year warranty, in case of equipment problems, we will respond within 48 hours after receiving feedback. During the warranty period, repair and replacement parts are free. Beyond the warranty period, we only charge the cost of various parts and free maintenance for life.

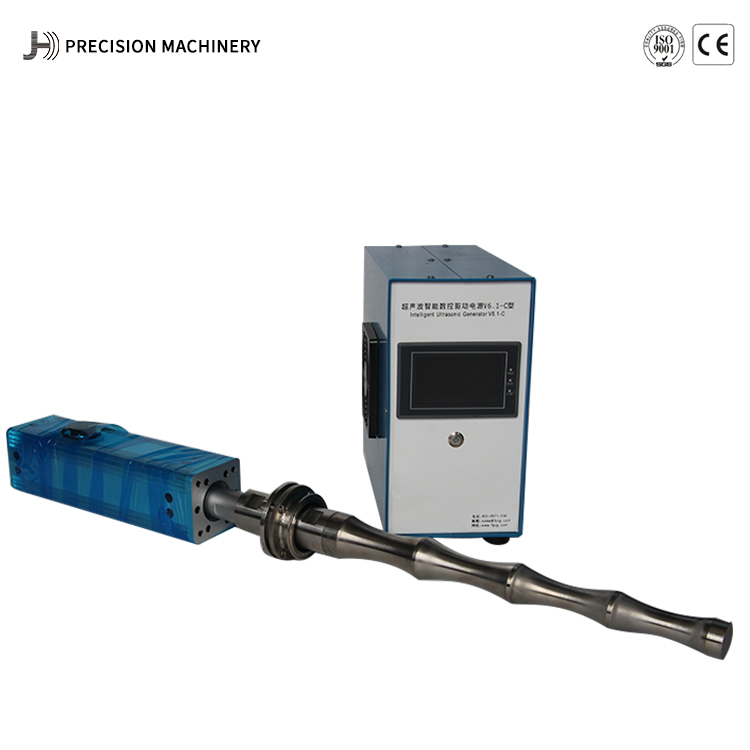

Product detail pictures:

Related Product Guide:

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic silica dispersion equipment – JH , The product will supply to all over the world, such as: Jamaica, Albania, Paraguay, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us