PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic pigments dispersion equipment – JH

PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic pigments dispersion equipment – JH Detail:

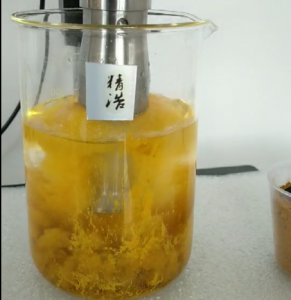

Pigments are dispersed into paints, coatings, and inks to provide color. But most of the metal compounds in pigments, such as: TiO2, SiO2, ZrO2, ZnO, CeO2 are insoluble substances. This requires an effective means of dispersion to disperse them into the corresponding medium. Ultrasonic dispersion technology is currently the best dispersion method.

Ultrasonic cavitation produces countless high and low pressure zones in the liquid. These high and low pressure zones continuously impact solid particles during the circulation process to deagglomerate them, reduce the size of the particles, and increase the surface contact area between the particles, so Disperse evenly into the solution.

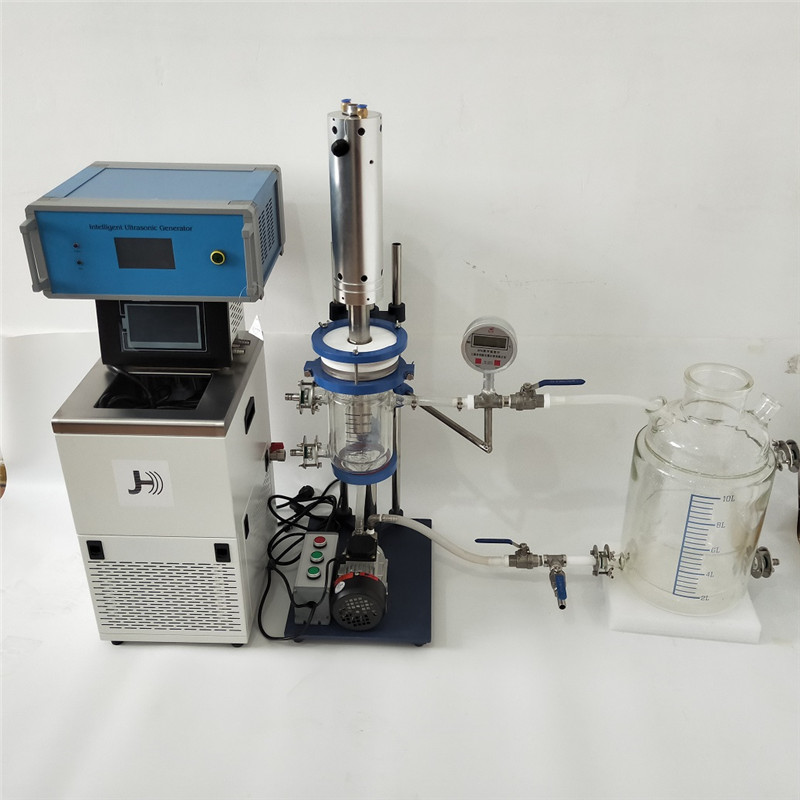

SPECIFICATIONS:

|

MODEL |

JH-BL5 JH-BL5L |

JH-BL10 JH-BL10L |

JH-BL20 JH-BL20L |

|

Frequency |

20Khz |

20Khz |

20Khz |

|

Power |

1.5Kw |

3.0Kw |

3.0Kw |

|

Input Voltage |

220/110V, 50/60Hz |

||

|

Processing Capacity |

5L |

10L |

20L |

|

Amplitude |

0~80μm |

0~100μm |

0~100μm |

|

Material |

Titanium alloy horn, glass tanks. |

||

|

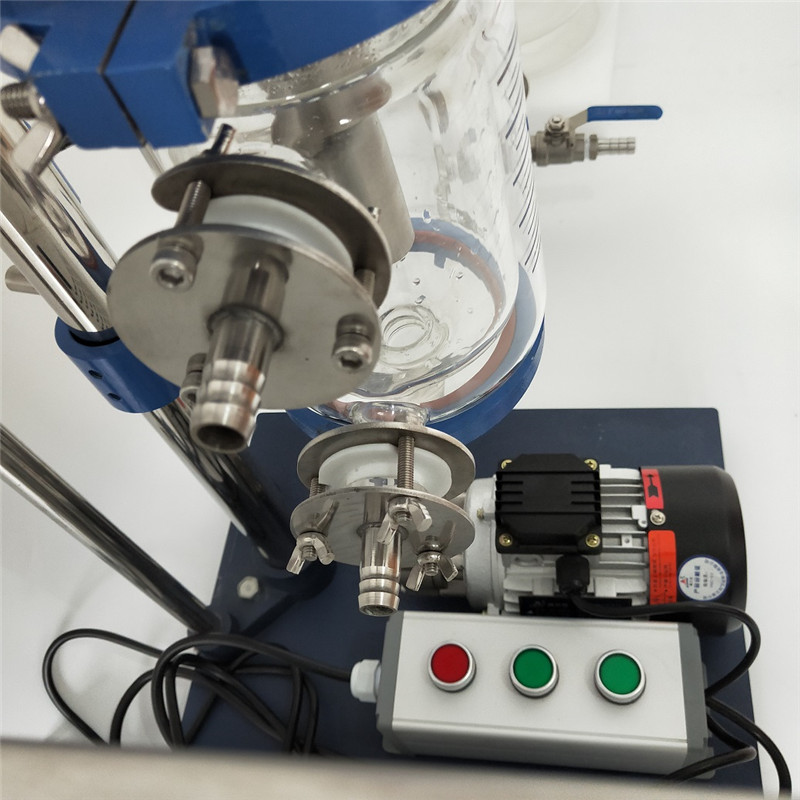

Pump Power |

0.16Kw |

0.16Kw |

0.55Kw |

|

Pump Speed |

2760rpm |

2760rpm |

2760rpm |

|

Max.Flow Rate |

10L/Min |

10L/Min |

25L/Min |

|

Horses |

0.21Hp |

0.21Hp |

0.7Hp |

|

Chiller |

Can control 10L liquid, from -5~100℃ |

Can control 30L liquid, from -5~100℃ |

|

|

Remarks |

JH-BL5L/10L/20L,match with a chiller. |

||

ADVANTAGES:

1. Significantly improve the color intensity.

2. Improve the scratch resistance, crack resistance and UV resistance of paints, coatings and inks.

3.Reduce particle sizes and remove entrapped air and/or dissolved gasses from the pigment suspension medium.

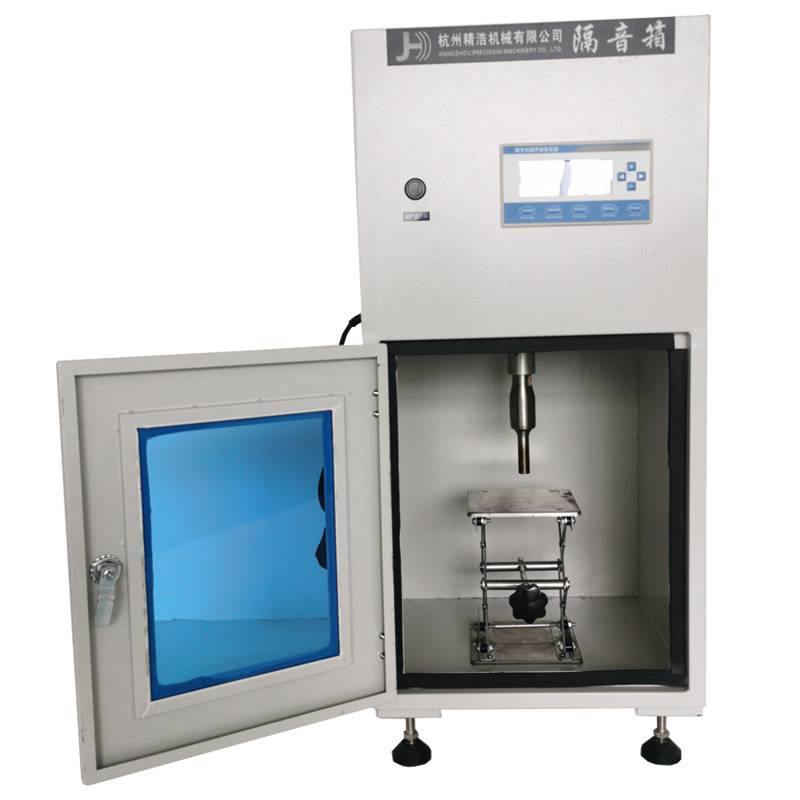

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for PriceList for 1500w Ultrasonic Disperser Emulsifier Processing Equipment - Ultrasonic pigments dispersion equipment – JH , The product will supply to all over the world, such as: Sao Paulo, Bangladesh, Jordan, Due to our good products and services, we have received good reputation and credibility from local and international customers. If you need more information and are interested in any of our products, please feel free to contact us. We look forward to becoming your supplier in the near future.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.