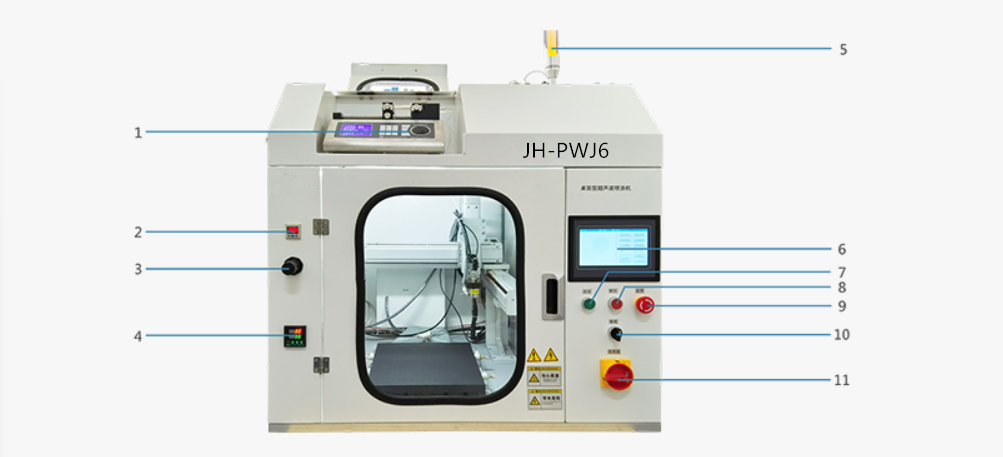

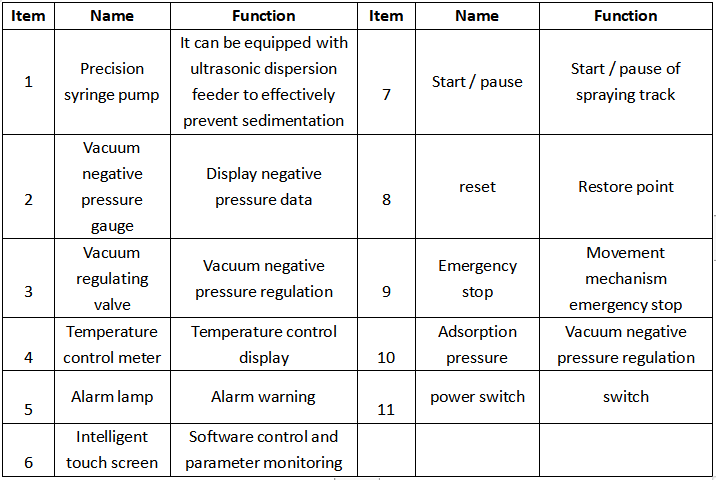

Precision ultrasonic spray coating system

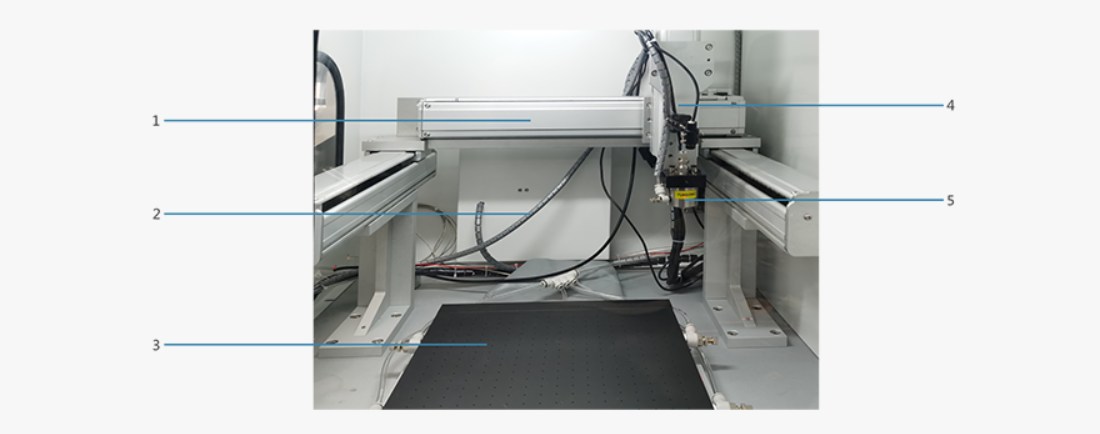

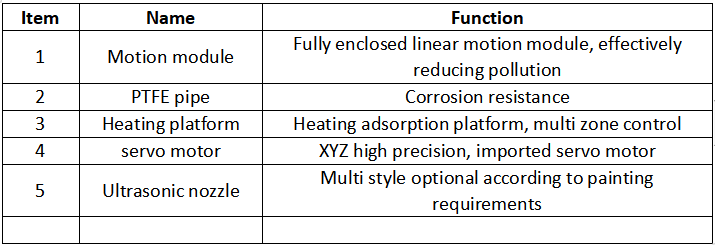

Ultrasonic nozzles operate by converting high frequency sound waves into mechanical energy that is transferred into a liquid, creating standing waves. As the liquid exits the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron sized droplets.

Unlike pressure nozzles, ultrasonic nozzles do not force liquids through a small orifice using high pressure in order to produce a spray. Liquid is fed through the center of a nozzle with a relatively large orifice, without pressure, and is atomized due to ultrasonic vibrations in the nozzle.

Every ultrasonic nozzle operates at a specific resonant frequency, which dictates the median droplet size. For example, a 60 kHz nozzle produces ,a median drop size of 20 microns (when spraying water). The higher the frequency, the smaller the median drop size.

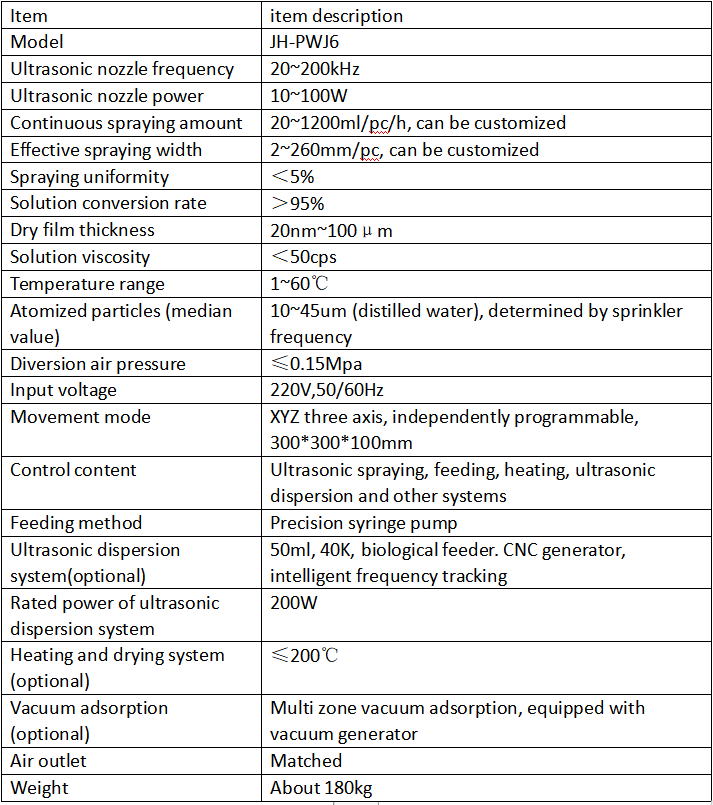

PARAMETERS:

Write your message here and send it to us