Manufacturer for Ultrasonic Dispersion System - Ultrasonic pigments dispersion equipment – JH

Manufacturer for Ultrasonic Dispersion System - Ultrasonic pigments dispersion equipment – JH Detail:

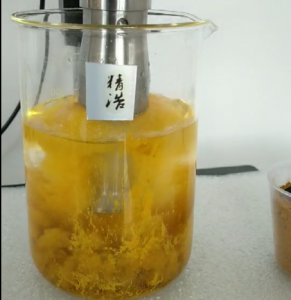

Pigments are dispersed into paints, coatings, and inks to provide color. But most of the metal compounds in pigments, such as: TiO2, SiO2, ZrO2, ZnO, CeO2 are insoluble substances. This requires an effective means of dispersion to disperse them into the corresponding medium. Ultrasonic dispersion technology is currently the best dispersion method.

Ultrasonic cavitation produces countless high and low pressure zones in the liquid. These high and low pressure zones continuously impact solid particles during the circulation process to deagglomerate them, reduce the size of the particles, and increase the surface contact area between the particles, so Disperse evenly into the solution.

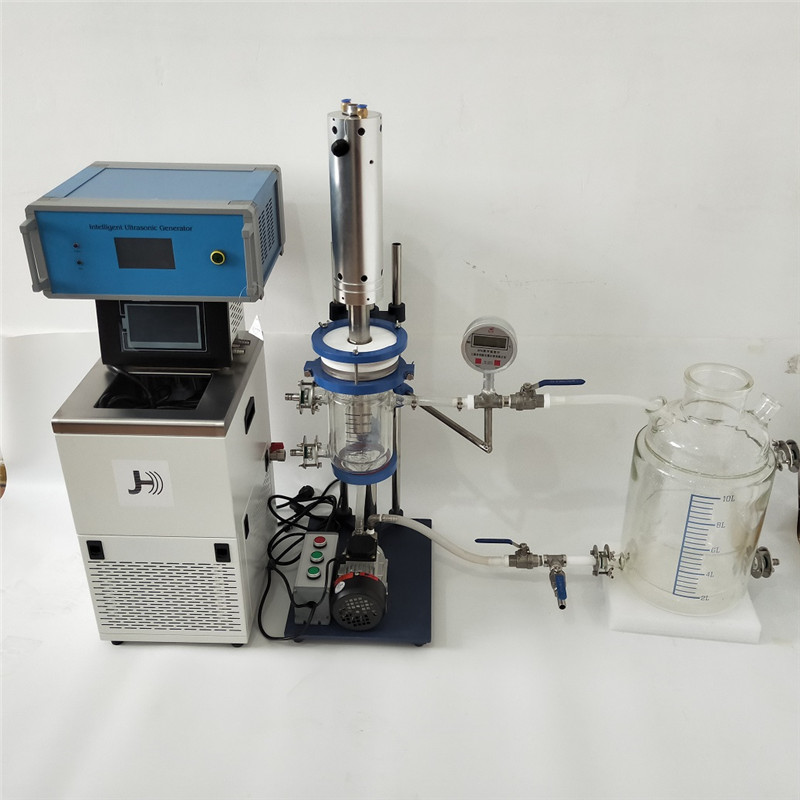

SPECIFICATIONS:

|

MODEL |

JH-BL5 JH-BL5L |

JH-BL10 JH-BL10L |

JH-BL20 JH-BL20L |

|

Frequency |

20Khz |

20Khz |

20Khz |

|

Power |

1.5Kw |

3.0Kw |

3.0Kw |

|

Input Voltage |

220/110V, 50/60Hz |

||

|

Processing Capacity |

5L |

10L |

20L |

|

Amplitude |

0~80μm |

0~100μm |

0~100μm |

|

Material |

Titanium alloy horn, glass tanks. |

||

|

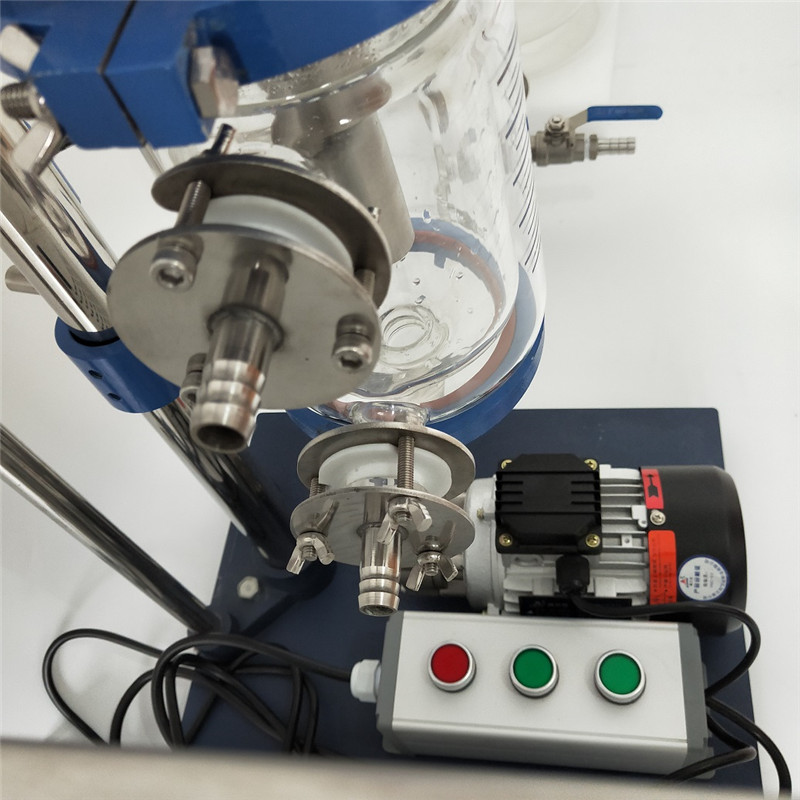

Pump Power |

0.16Kw |

0.16Kw |

0.55Kw |

|

Pump Speed |

2760rpm |

2760rpm |

2760rpm |

|

Max.Flow Rate |

10L/Min |

10L/Min |

25L/Min |

|

Horses |

0.21Hp |

0.21Hp |

0.7Hp |

|

Chiller |

Can control 10L liquid, from -5~100℃ |

Can control 30L liquid, from -5~100℃ |

|

|

Remarks |

JH-BL5L/10L/20L,match with a chiller. |

||

ADVANTAGES:

1. Significantly improve the color intensity.

2. Improve the scratch resistance, crack resistance and UV resistance of paints, coatings and inks.

3.Reduce particle sizes and remove entrapped air and/or dissolved gasses from the pigment suspension medium.

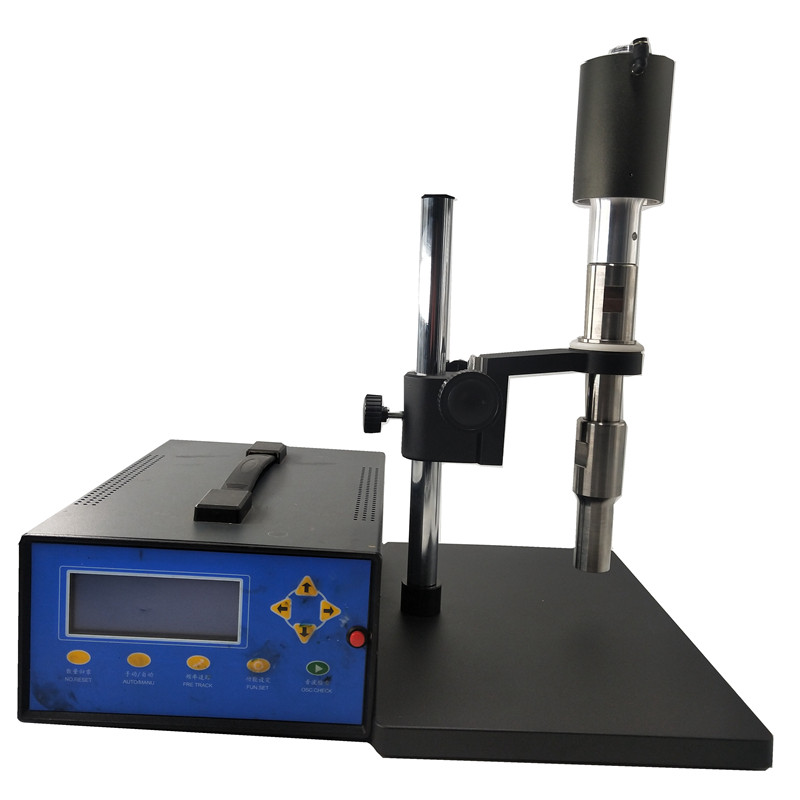

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Manufacturer for Ultrasonic Dispersion System - Ultrasonic pigments dispersion equipment – JH , The product will supply to all over the world, such as: Colombia, Senegal, Mexico, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.