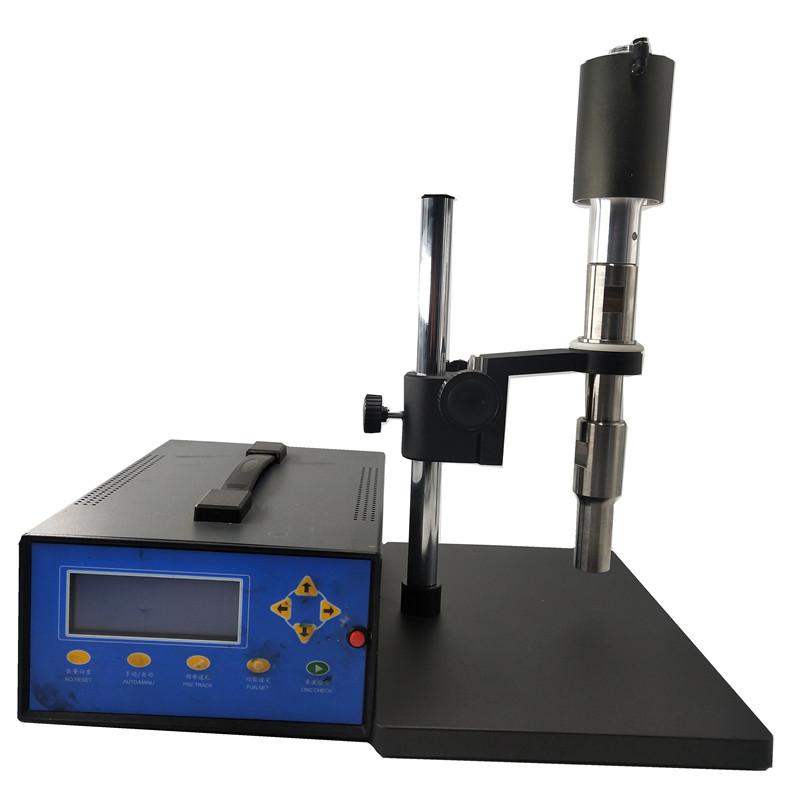

Laboratory ultrasonic CBD extraction equipment

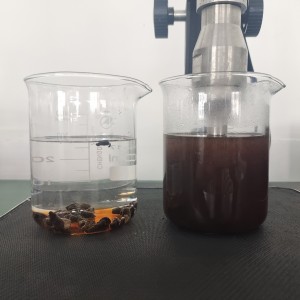

Ultrasonic extraction addresses the extremely problematic fact that cannabinoids, like THC and CBD, are naturally hydrophobic. Without harsh solvents, it is often difficult to expel the precious cannabinoids from within the cell interior. To increase the bioavailability of the final product, producers need to find extraction methods that break down the tough cell wall.

The technology behind ultrasonic extraction is anything but easy to understand. In essence, sonication relies on ultrasonic waves. A probe is inserted into a solvent mixture, and the probe then emits a series of high and low-pressure sound waves. This process essentially creates microscopic currents, eddies, and pressurized streams of liquid, forming a particularly harsh environment.These ultrasonic sound waves, which emit at a speed of up to 20,000 per second, create an environment that breaks through cellular walls. The forces which typically work to hold the cell together are no longer viable within the alternating pressurized atmosphere created by the probe.Millions upon millions of tiny bubbles are created, which subsequently pop, leading to the complete breakdown of the protective cell wall. As the cell walls break down, the inner materials are released directly into the solvent, thus creating a potent emulsion.

SPECIFICATIONS:

| Model | JH1500W-20 |

| Frequency | 20Khz |

| Power | 1.5Kw |

| Input voltage | 110/220V,50/60Hz |

| Power adjustable | 20~100% |

| Probe diameter | 30/40mm |

| Horn material | Titanium alloy |

| Shell diameter | 70mm |

| Flange | 64mm |

| Horn length | 185mm |

| Generator | CNC generator, automatic frequency tracking |

| Processing capacity | 100~3000ml |

| Material viscosity | ≤6000cP |

STEP BY STEP:

Ultrasonic Extraction: Ultrasonic extraction can be easily performed in batch or continuous flow-through mode – depending on your process volume. The extraction process is very rapid and yields in a high amount of active compounds.

Filtration: Filter the plant-liquid mixture through a paper filter or a filter bag to remove the solid plant parts from the liquid.

Evaporation: For the separation of the CBD oil from the solvent, commonly a rotor-evaporator is used. The solvent, e.g. ethanol, can be recaptured and reused.

Nano-Emulsification: By sonication, the purified CBD oil can be processed into a stable nanoemulsion, which offers superb bioavailability.

ADVANTAGES:

short extraction time

high extraction rate

more complete extraction

mild, non-thermal treatment

easy integration and safe operation

no hazardous / toxic chemicals, no impurities

energy-efficient

green extraction: environmental-friendly

SCALE