Industrial Flow Ultrasonic Extraction Equipment

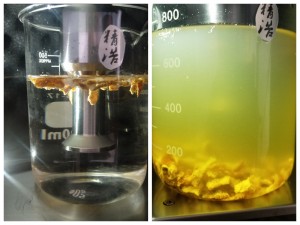

Ultrasonic extraction is based on the principle of acoustic cavitation. Immersing the ultrasonic probe in a herbaceous plant slurry or a mixed solution of plant roots, stems, leaves, flowers and green solvents can cause strong cavitation and shear forces. Destroy plant cells and release the substances in them.

JH provide industrial ultrasonic extraction lines of different scales and different forms. The following are the parameters of small and medium-sized equipment. If you need a larger scale, please contact us directly for details.

SPECIFICATIONS:

| MODEL | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | No, but can be customized | |||

ADVANTAGES:

1. Herbal compounds are temperature sensitive substances. Ultrasonic extraction can achieve low temperature operation, ensure that the extracted components are not destroyed, and improve bioavailability.

2. The energy of ultrasonic vibration is very powerful, which reduces the dependence on the solvent in the extraction process. The solvent of ultrasonic extraction can be water, ethanol or a mixture of the two.

3. The extract has high quality, strong stability, fast extraction speed and large output.