High Quality Ultrasonic Emulsification Emulsifying Making Machine - ultrasonic biodiesel processor for oil water nanoemulsion mixing – JH

High Quality Ultrasonic Emulsification Emulsifying Making Machine - ultrasonic biodiesel processor for oil water nanoemulsion mixing – JH Detail:

When you make biodiesel, slow reaction kinetics and poor mass transfer are lowering your biodiesel plant capacity and your biodiesel yield and quality. JH ultrasonic reactors improve the transesterification kinetics significantly. Therefore lower excess methanol and less catalyst are required for biodiesel processing. Biodiesel is commonly produced in batch reactors using heat and mechanical mixing as energy input. Ultrasonic cavitational mixing is an effective alternative means to achieve a better mixing in commercial biodiesel processing. Ultrasonic cavitation provides the necessary activation energy for the industrial biodiesel transesterification. Ultrasonic processing of biodiesel involves the following steps:

1.The vegetable oil or animal fat is being mixed with the methanol (which makes methyl esters) or ethanol (for ethyl esters) and sodium or potassium methoxide or hydroxide.

2.The mix is heated, e.g. to temperatures between 45 and 65degC.

3.The heated mix is being sonicated inline for 5 to 30 seconds.

4.Glycerin drops out or is separated using centrifuges.

5.The converted biodiesel is washed with water. Most commonly, the sonication is performed at an elevated pressure (1 to 3bar, gauge pressure) using a feed pump and an adjustable back-pressure valve next to the flow cell.

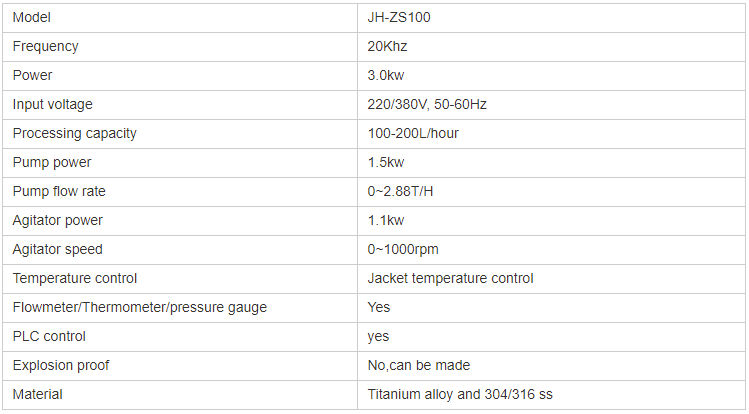

SPECIFICATIONS:

Product detail pictures:

Related Product Guide:

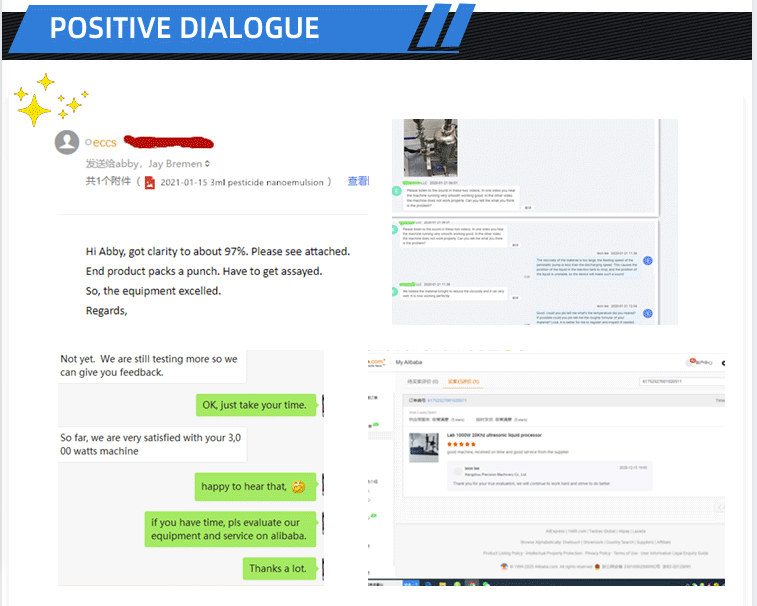

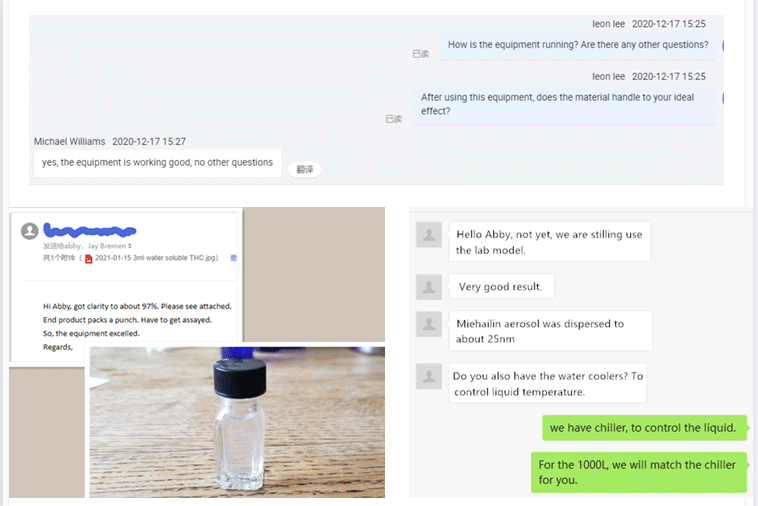

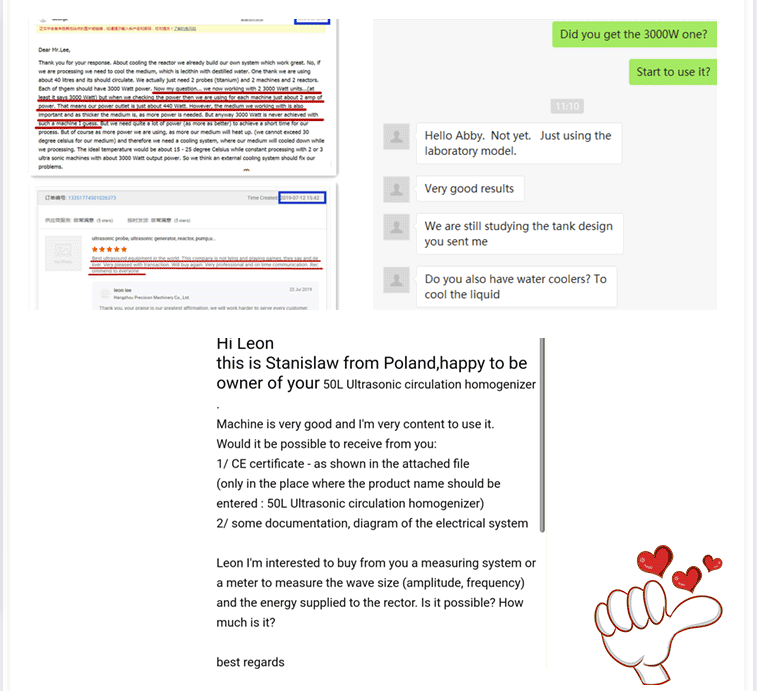

To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for High Quality Ultrasonic Emulsification Emulsifying Making Machine - ultrasonic biodiesel processor for oil water nanoemulsion mixing – JH , The product will supply to all over the world, such as: Houston, New Orleans, Rome, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.