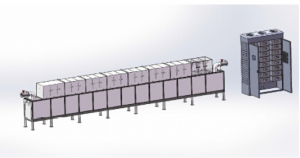

High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH

High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH Detail:

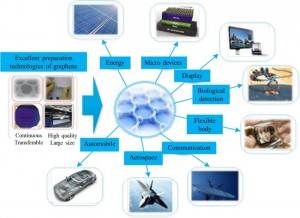

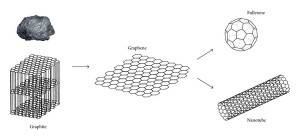

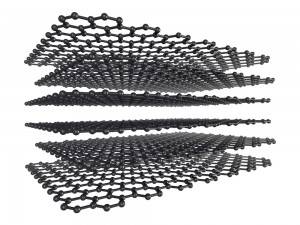

Due to the extraordinary material properties of graphene, such as: strength, hardness, service life, etc. In recent years, graphene has become more and more widely used. In order to incorporate graphene into the composite material and play its role, it must be dispersed into individual nanosheets. The higher the degree of deagglomeration, the more obvious the role of graphene.

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

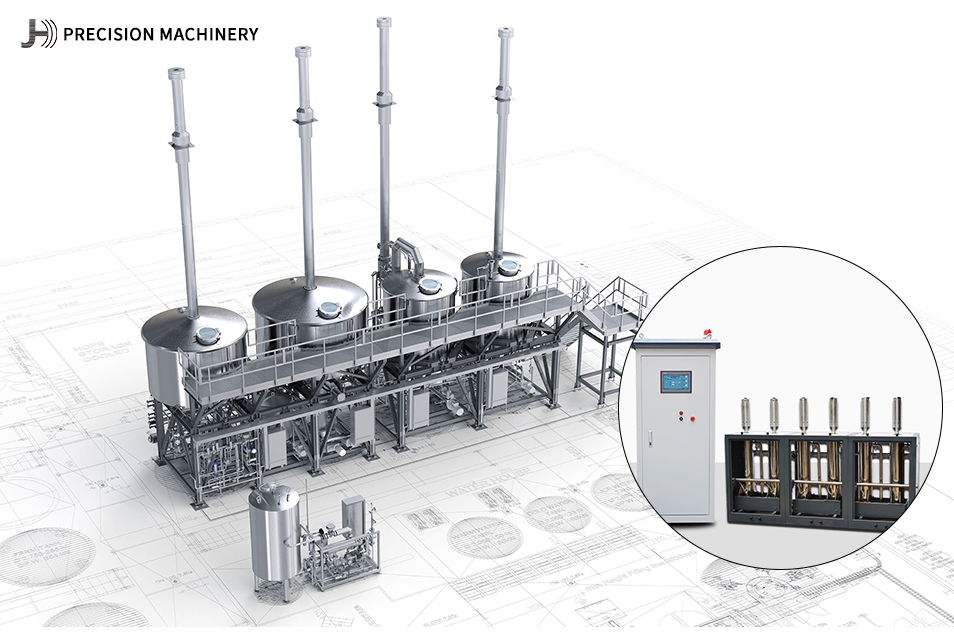

SPECIFICATIONS:

|

Model |

JH-JX10 |

JH-JX25 |

JH-JX50 |

JH-JX100 |

JH-JX200 |

JH-JX300 |

|

Yearly output |

10T |

25T |

50T |

100T |

200T |

300T |

|

Install area |

5㎡ |

10㎡ |

20㎡ |

40㎡ |

60㎡ |

80㎡ |

|

Total power |

18000W |

36000W |

72000W |

14000W |

288000W |

432000W |

|

QTY of ultrasonic equipment |

6 |

12 |

24 |

48 |

96 |

144 |

|

Input voltage |

220V /380V,50Hz |

|||||

|

Frequency |

20KHz±1KHz |

|||||

ADVANTAGES:

1.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

2.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

3.Can be dispersed into high viscosity and high concentration solutions.

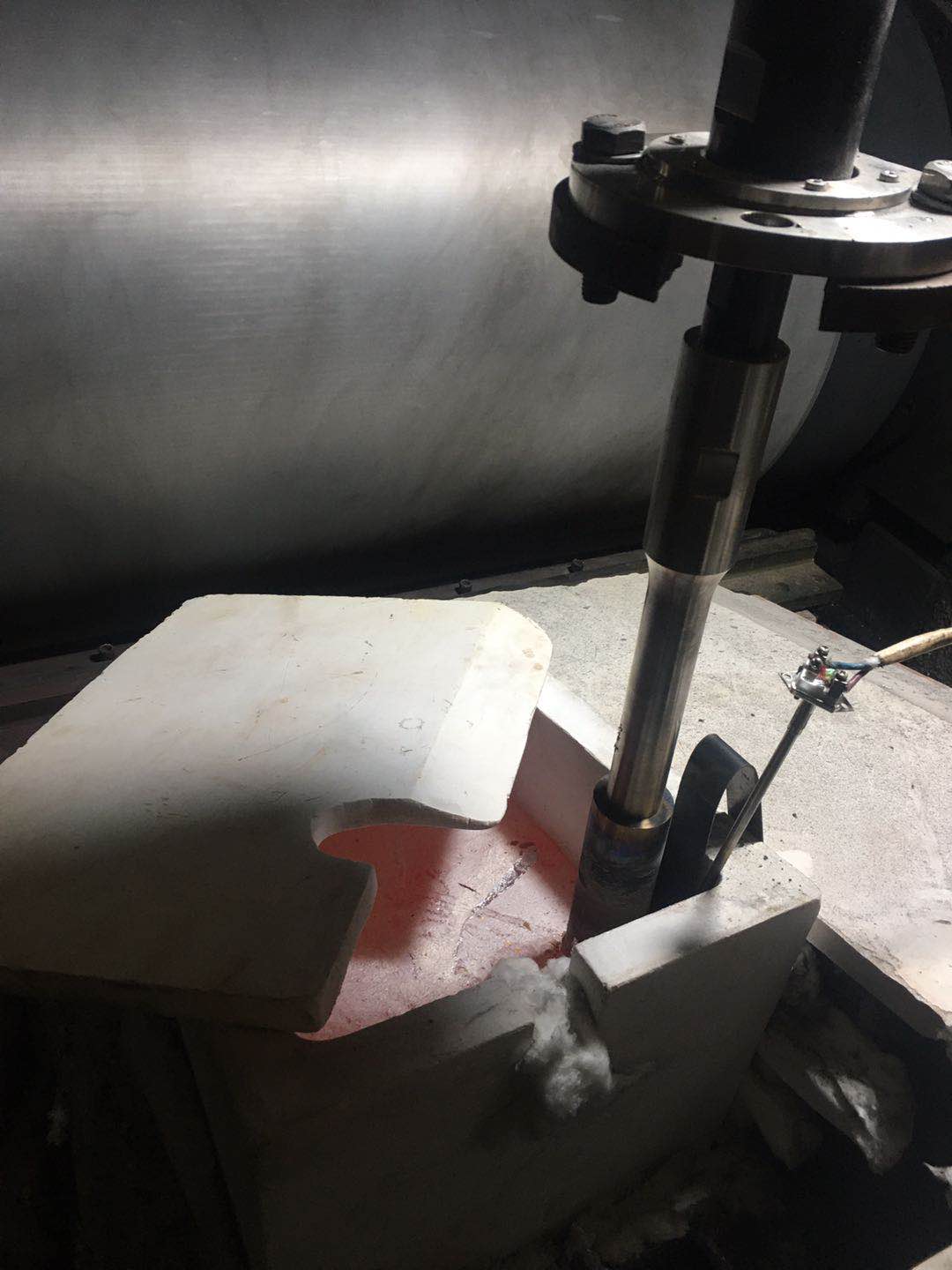

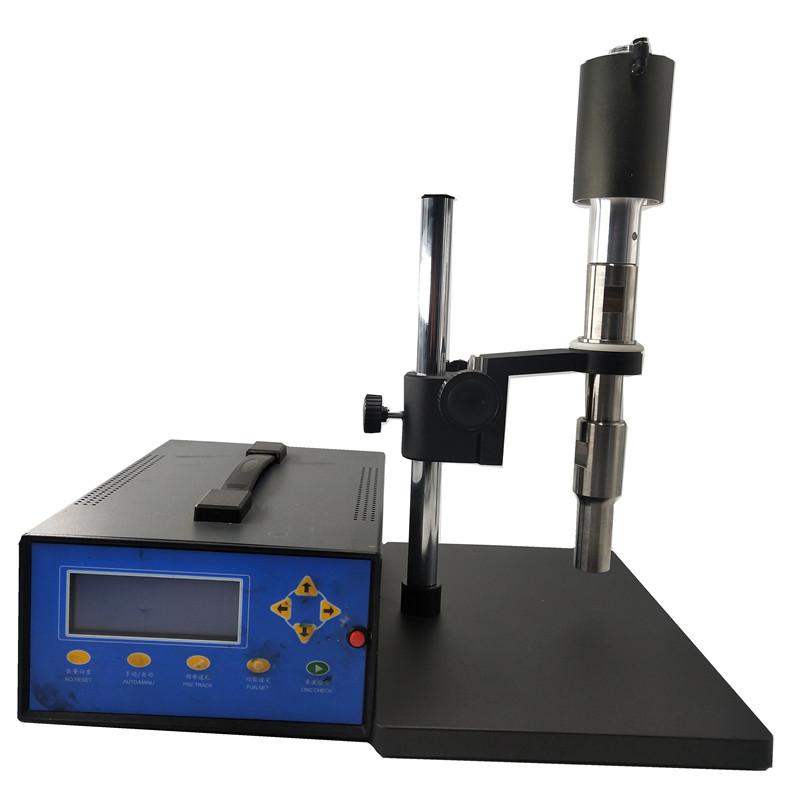

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for High Quality for Homogenizing And Dispersing Machine - Ultrasonic Graphene Dispersing Equipment – JH , The product will supply to all over the world, such as: South Africa, Saudi Arabia, Manila, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.