Good Quality Ultrasonic Emulsification Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH

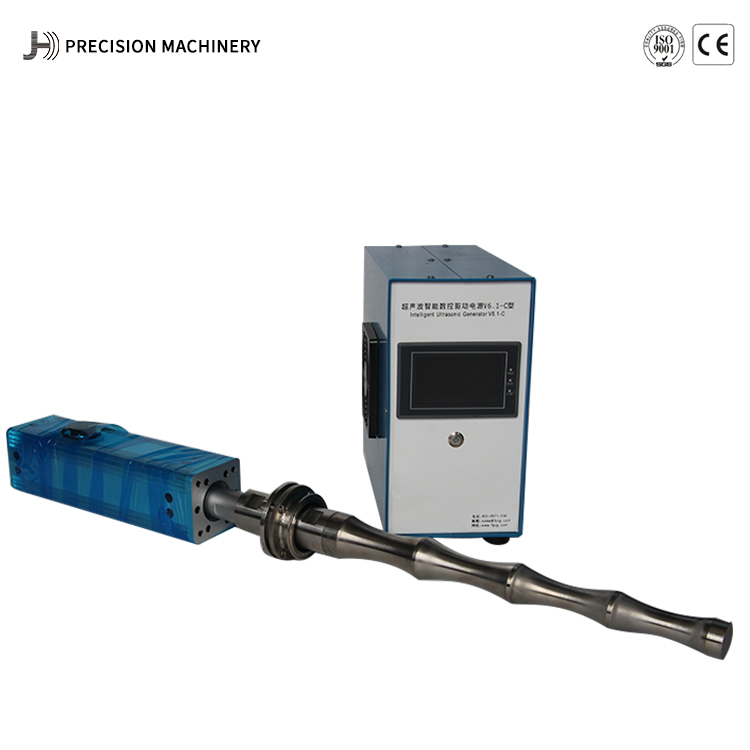

Good Quality Ultrasonic Emulsification Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH Detail:

When you make biodiesel, slow reaction kinetics and poor mass transfer are lowering your biodiesel plant capacity and your biodiesel yield and quality. JH ultrasonic reactors improve the transesterification kinetics significantly. Therefore lower excess methanol and less catalyst are required for biodiesel processing. Biodiesel is commonly produced in batch reactors using heat and mechanical mixing as energy input. Ultrasonic cavitational mixing is an effective alternative means to achieve a better mixing in commercial biodiesel processing. Ultrasonic cavitation provides the necessary activation energy for the industrial biodiesel transesterification. Ultrasonic processing of biodiesel involves the following steps:

1.The vegetable oil or animal fat is being mixed with the methanol (which makes methyl esters) or ethanol (for ethyl esters) and sodium or potassium methoxide or hydroxide.

2.The mix is heated, e.g. to temperatures between 45 and 65degC.

3.The heated mix is being sonicated inline for 5 to 30 seconds.

4.Glycerin drops out or is separated using centrifuges.

5.The converted biodiesel is washed with water. Most commonly, the sonication is performed at an elevated pressure (1 to 3bar, gauge pressure) using a feed pump and an adjustable back-pressure valve next to the flow cell.

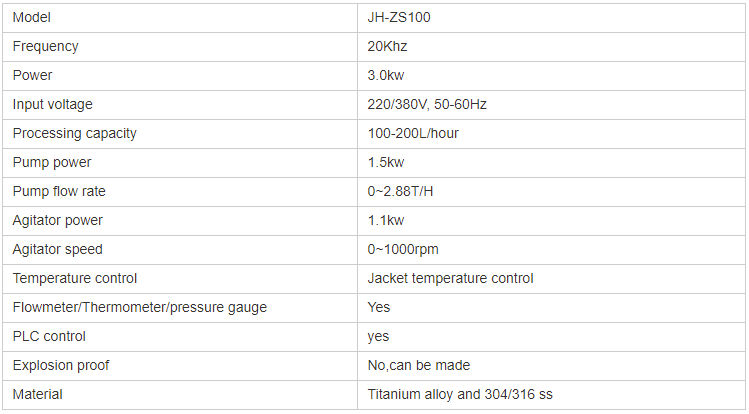

SPECIFICATIONS:

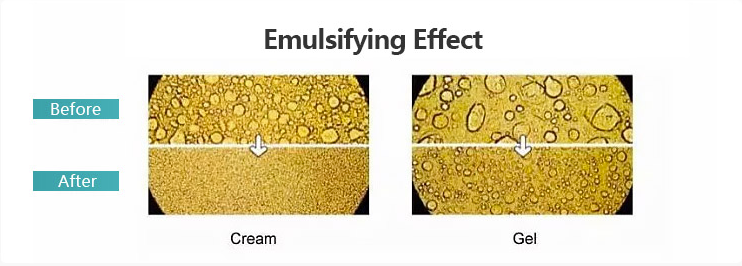

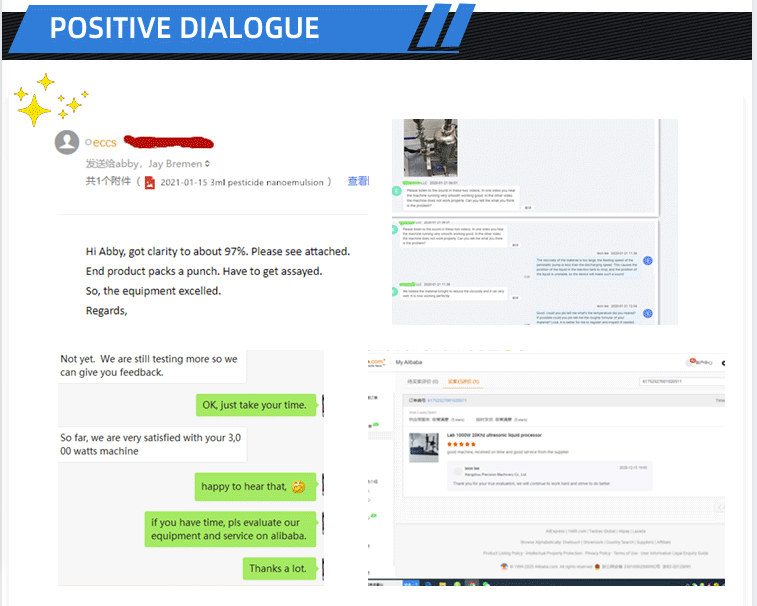

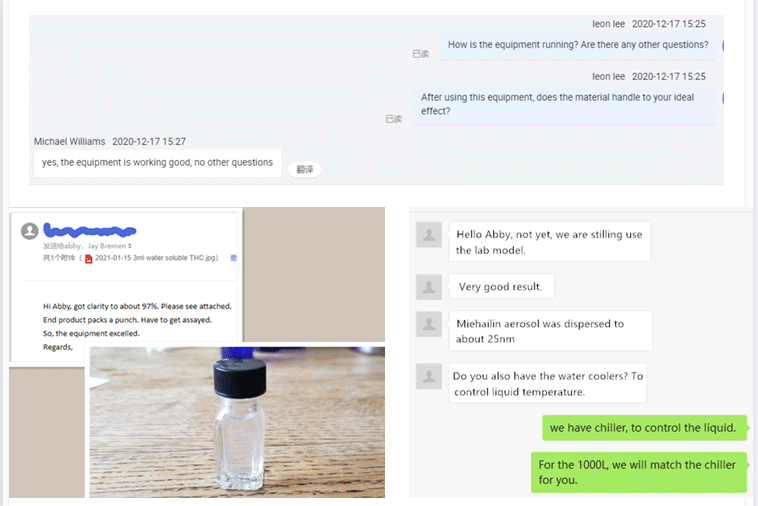

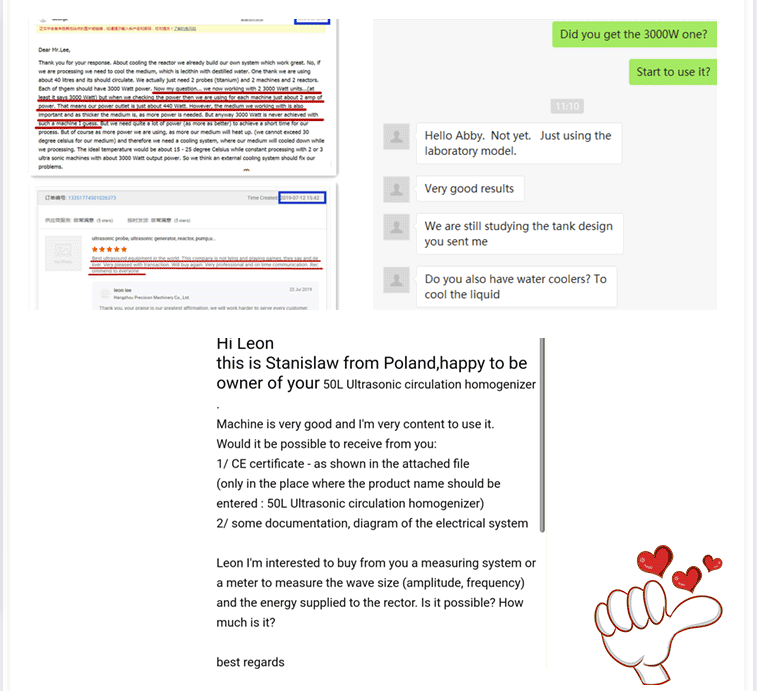

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Good Quality Ultrasonic Emulsification Equipment - ultrasonic biodiesel reactor continuous liquid chemic mixer for nanoemulsion emulsifier – JH , The product will supply to all over the world, such as: Azerbaijan, Ghana, Liverpool, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.