Good Quality Ultrasonic Dispersion Processor - Ultrasonic Graphene Dispersing Equipment – JH

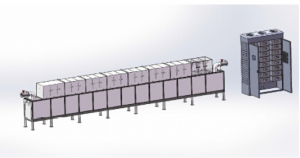

Good Quality Ultrasonic Dispersion Processor - Ultrasonic Graphene Dispersing Equipment – JH Detail:

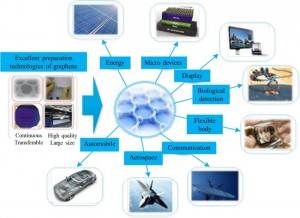

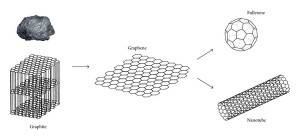

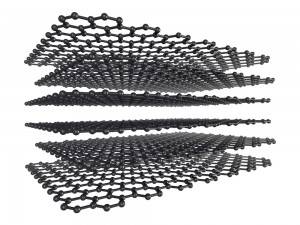

Due to the extraordinary material properties of graphene, such as: strength, hardness, service life, etc. In recent years, graphene has become more and more widely used. In order to incorporate graphene into the composite material and play its role, it must be dispersed into individual nanosheets. The higher the degree of deagglomeration, the more obvious the role of graphene.

Ultrasonic vibration overcomes the van der Waals force with a high shear force of 20,000 times per second, thereby preparing graphene with high conductivity, good dispersion and high concentration. Since the ultrasonic treatment process can be precisely controlled, the chemical and crystal structure of the graphene obtained by ultrasonic dispersion will not be destroyed.

SPECIFICATIONS:

|

Model |

JH-JX10 |

JH-JX25 |

JH-JX50 |

JH-JX100 |

JH-JX200 |

JH-JX300 |

|

Yearly output |

10T |

25T |

50T |

100T |

200T |

300T |

|

Install area |

5㎡ |

10㎡ |

20㎡ |

40㎡ |

60㎡ |

80㎡ |

|

Total power |

18000W |

36000W |

72000W |

14000W |

288000W |

432000W |

|

QTY of ultrasonic equipment |

6 |

12 |

24 |

48 |

96 |

144 |

|

Input voltage |

220V /380V,50Hz |

|||||

|

Frequency |

20KHz±1KHz |

|||||

ADVANTAGES:

1.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

2.A mixture of green solvents such as organic acids, water and alcohol can be used to reduce the damage to the dispersed graphene.

3.Can be dispersed into high viscosity and high concentration solutions.

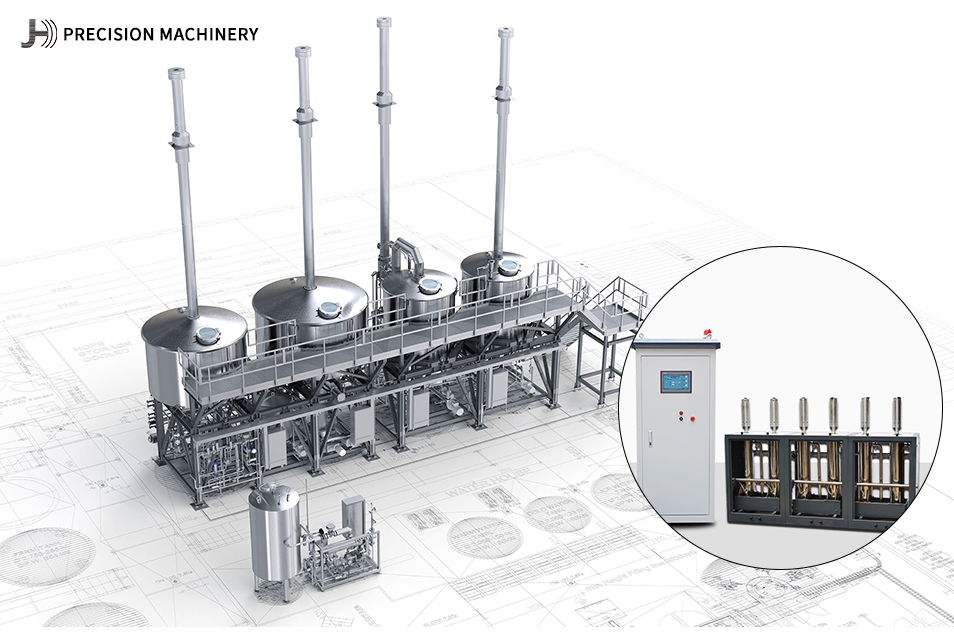

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for Good Quality Ultrasonic Dispersion Processor - Ultrasonic Graphene Dispersing Equipment – JH , The product will supply to all over the world, such as: Plymouth, Paris, Turkmenistan, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!