Good Quality Industrial Scale Ultrasonic Circulation System – ultrasonic inline water treatment homogenizer – JH

Good Quality Industrial Scale Ultrasonic Circulation System – ultrasonic inline water treatment homogenizer – JH Detail:

Ultrasonic homogenizing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed.

When ultrasonic processors are used as homogenizers, the objective is to reduce small particles in a liquid to improve uniformity and stability. These particles (disperse phase) can be either solids or liquids. A reduction in the mean diameter of the particles increases the number of individual particles. This leads to a reduction of the average particle distance and increases the particle surface area.

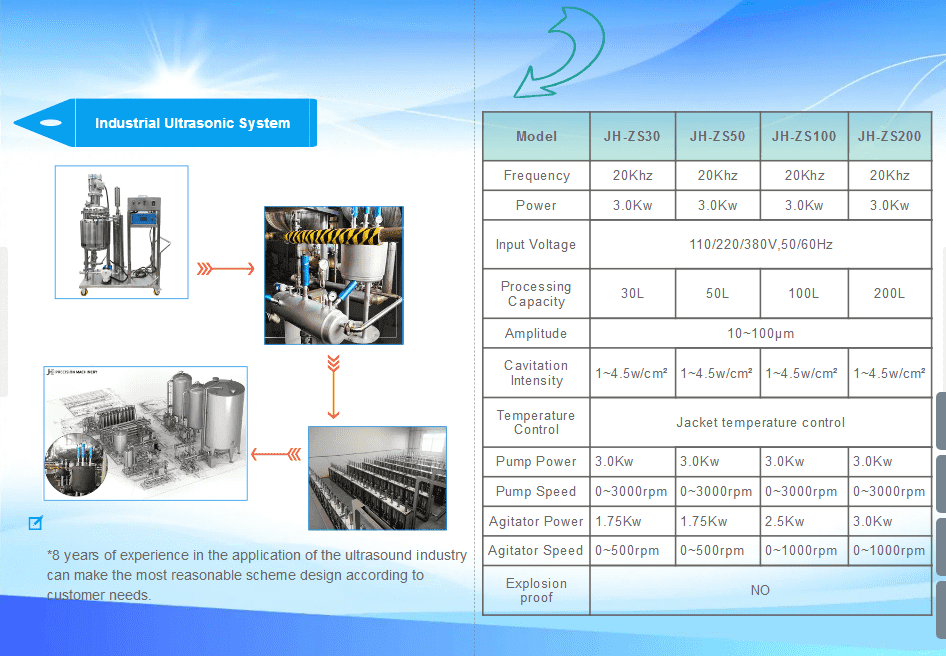

Due to the design of continuous flow tank, each batch or daily product is not limited. In principle, the circulation can be realized when the output of each batch is more than 50L. This kind of ultrasonic water treatment homogenizer is very popular in medium and large enterprises or engineering projects.

SPECIFICATIONS:

ADVANTAGES:

1) Intelligent control technology, stable ultrasonic energy output,stable work for 24 hours per day.

2) Automatic frequency tracking mode, ultrasonic transducer working frequency real-time tracking.

3) Multiple protection mechanisms to extend service life to more than 5 years.

4) Energy focus design, high output density, improve efficiency to 200 times in the suitable area.

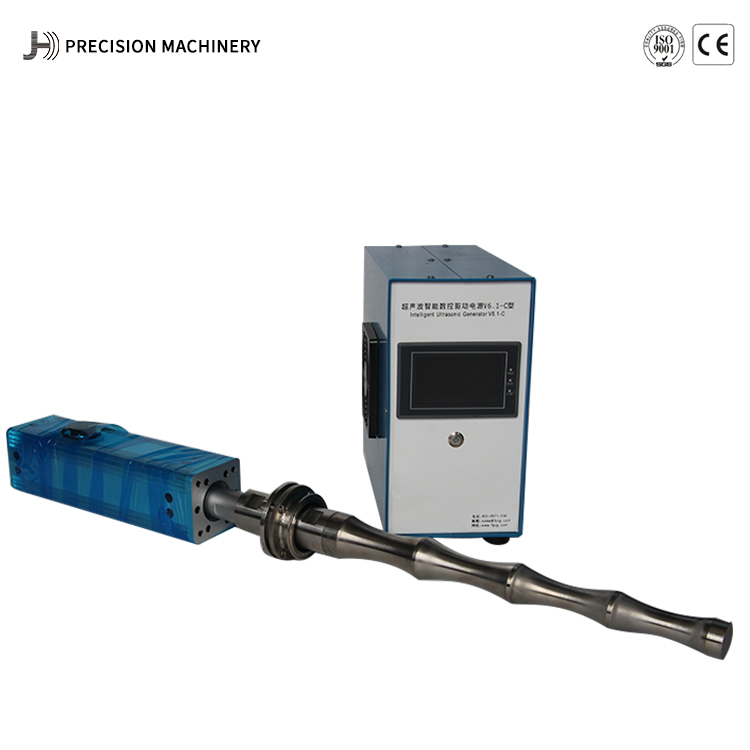

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Good Quality Industrial Scale Ultrasonic Circulation System – ultrasonic inline water treatment homogenizer – JH , The product will supply to all over the world, such as: Botswana, Zurich, Orlando, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Write your message here and send it to us