Factory wholesale Ultrasonic Processors For Biodiesel Production - Industrial ultrasonic liquid processor – JH

Factory wholesale Ultrasonic Processors For Biodiesel Production - Industrial ultrasonic liquid processor – JH Detail:

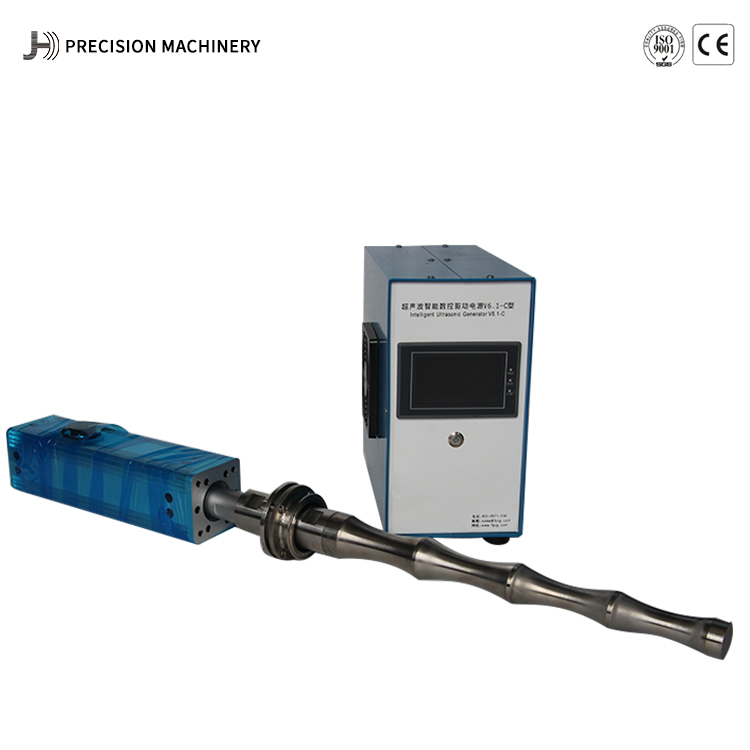

Ultrasonic liquid processor can be used for liquid dispersion, extraction, emulsification and homogenization. Such as: dispersed graphene, liposomes, coatings, alumina, silica, nanomaterials, carbon nanotubes, carbon black, etc. Extract Chinese medicine, CBD, protein, nucleic acid, etc. Emulsification: CBD oil, biodiesel, etc. Homogenization can also be used for cell lysis, tissue destruction, DNA construction, etc.

SPECIFICATIONS:

| Model | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

ADVANTAGES:

1. The energy output of the equipment is stable, and it can work continuously for 24 hours.

2. Large amplitude, wide radiation area and good processing effect.

3. Automatically track the frequency and amplitude to ensure that the probe amplitude does not change due to load changes.

4. It can handle temperature sensitive materials well.

WHY CHOOSE US?

1. Our sales team has an average working experience of more than 5 years. Pre-sales can give you reasonable suggestions to help you choose the most suitable product.

2. Each application field has a corresponding engineer who can design more cost-effective solutions and products for you.

3. The responsibility of the production department is attributed to each employee to ensure that every step of production is more rigorous and the quality of the product is stable.

4. We have an after-sales team that speaks English. If you encounter problems when using the product, our after-sales team can give you direct guidance.

Product detail pictures:

Related Product Guide:

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Factory wholesale Ultrasonic Processors For Biodiesel Production - Industrial ultrasonic liquid processor – JH , The product will supply to all over the world, such as: Finland, Eindhoven, Mauritius, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.