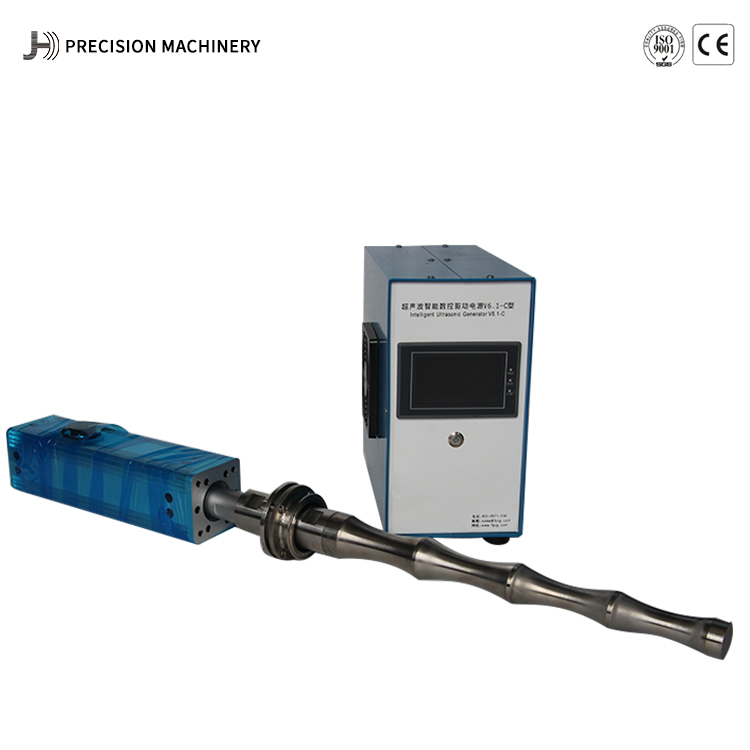

Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - Ultrasonic tattoo inks dispersion equipment – JH

Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - Ultrasonic tattoo inks dispersion equipment – JH Detail:

Tattoo inks are composed of pigments combined with carriers and are used for tattoos. Tattoo ink can use a variety of colors of tattoo ink, they can be diluted or mixed to produce other colors. In order to get a clear display of tattoo color, it is necessary to disperse the pigment into the ink uniformly and stably. Ultrasonic dispersion of pigments is an effective method.

Ultrasonic cavitation produces countless small bubbles. These small bubbles form, grow and burst in several wave bands. This process will produce some extreme local conditions, such as strong shear force and microjet. These forces disperse the original large droplets into nano-particles.In this case,pigments can be uniformly and effectively dispersed into various inks.

SPECIFICATIONS:

| MODEL | JH-ZS5JH-ZS5L | JH-ZS10JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

ADVANTAGES:

1. Significantly improve the color intensity.

2. Improve the scratch resistance, crack resistance and UV resistance of paints, coatings and inks.

3.Reduce particle sizes and remove entrapped air and/or dissolved gasses from the pigment suspension medium.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - Ultrasonic tattoo inks dispersion equipment – JH , The product will supply to all over the world, such as: Macedonia, United Arab Emirates, Peru, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.