Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - ultrasonic carbon nanotubes dispersion machine – JH

Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - ultrasonic carbon nanotubes dispersion machine – JH Detail:

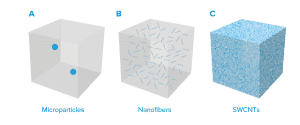

Carbon nanotubes have many uses, and can be used in adhesives, coatings, polymers and as conductive fillers in plastics. By using carbon nanotubes, the polymer’s high temperature resistance, corrosion resistance, pressure resistance and wear resistance have been significantly improved.

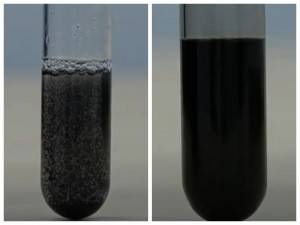

Ultrasonic waves generate powerful shearing forces through 20,000 vibrations per second. The bonding force between carbon nanotubes can be overcome, and the tubes are separated evenly. Generally, the crude nanotube dispersion is pre-mixed by mechanical stirring, and then further dispersed into small beams or single carbon nanotubes using ultrasonic waves. It is recommended to use pipeline ultrasonic equipment.

SPECIFICATIONS:

| Model | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | NO | |||

ADVANTAGES:

1.Compared with the dispersion in the traditional harsh environment, ultrasonic dispersion can reduce the damage to the structure of single-walled carbon nanotubes and maintain a long single-walled carbon nanotube.

2.It can be completely and evenly dispersed to better achieve the performance of carbon nanotubes.

3.It can quickly disperse carbon nanotubes, avoid degradation of carbon nanotubes, and obtain high concentration carbon nanotube solutions.

Product detail pictures:

Related Product Guide:

We also present product or service sourcing and flight consolidation products and services. We have our possess manufacturing facility and sourcing place of work. We can easily supply you with almost every type of product or service connected to our item variety for Factory Free sample Ultrasonic Emulsifying Ultrasonic Sonochemistry Reactor - ultrasonic carbon nanotubes dispersion machine – JH , The product will supply to all over the world, such as: Armenia, Brisbane, Seattle, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.