China wholesale Mixing Equipment For Mixing Liquid Chemicals - Ultrasonic liquid mixing equipment – JH

China wholesale Mixing Equipment For Mixing Liquid Chemicals - Ultrasonic liquid mixing equipment – JH Detail:

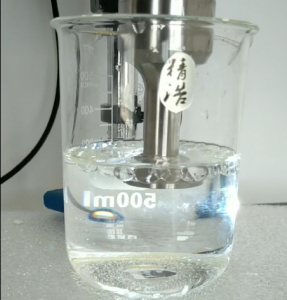

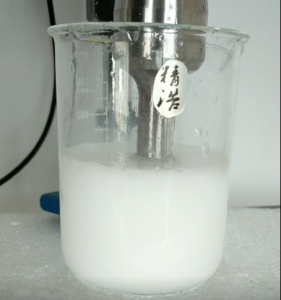

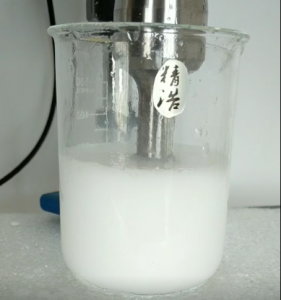

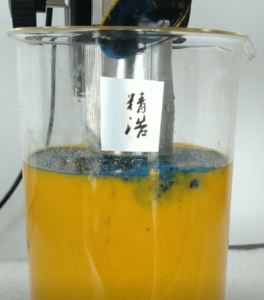

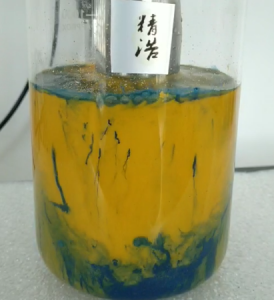

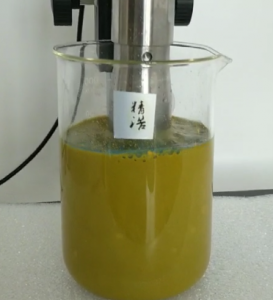

The mixing of powders into liquids is a common step in the formulation of various products, such as paint, ink, shampoo, beverages, or polishing media. The individual particles are held together by attraction forces of various physical and chemical nature, including van der Waals forces and liquid surface tension. This effect is stronger for higher viscosity liquids, such as polymers or resins. The attraction forces must be overcome on order to deagglomerate and disperse the particles into liquid media.

Ultrasonic cavitation in liquids causes high speed liquid jets of up to 1000km/h (approx. 600mph). Such jets press liquid at high pressure between the particles and separate them from each other. Smaller particles are accelerated with the liquid jets and collide at high speeds. This makes ultrasound an effective means for the dispersing and deagglomeration but also for the milling and fine grinding of micron-size and sub micron-size particles.

The dispersing and deagglomeration of solids into liquids is an important application of ultrasonic devices. Ultrasonic cavitation generates high shear that breaks particle agglomerates into single dispersed particles.

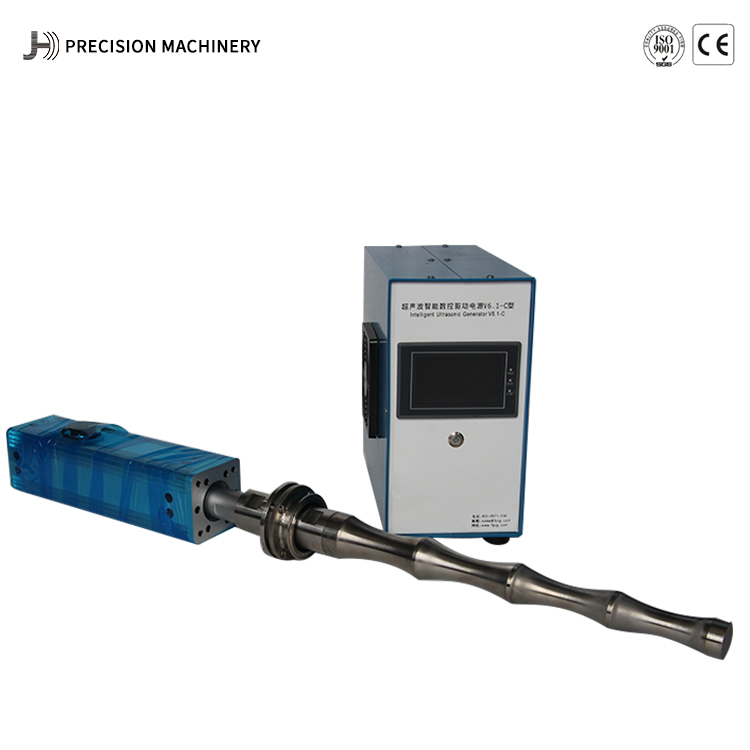

SPECIFICATIONS:

| MODEL | JH-ZS5/JH-ZS5L | JH-ZS10/JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

ADVANTAGES:

1.The device can work continuously for 24 hours, and the life of the transducer is up to 50000 hours.

2.The horn can be customized according to different industries and different working environments in order to achieve the best processing effect.

3.Can be connected to PLC, making operation and information recording more convenient.

4.Automatically adjust the output energy according to the change of liquid to ensure that the dispersion effect is always in the best state.

5.Can handle temperature sensitive liquids.

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for China wholesale Mixing Equipment For Mixing Liquid Chemicals - Ultrasonic liquid mixing equipment – JH , The product will supply to all over the world, such as: Guatemala, Uruguay, Irish, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!