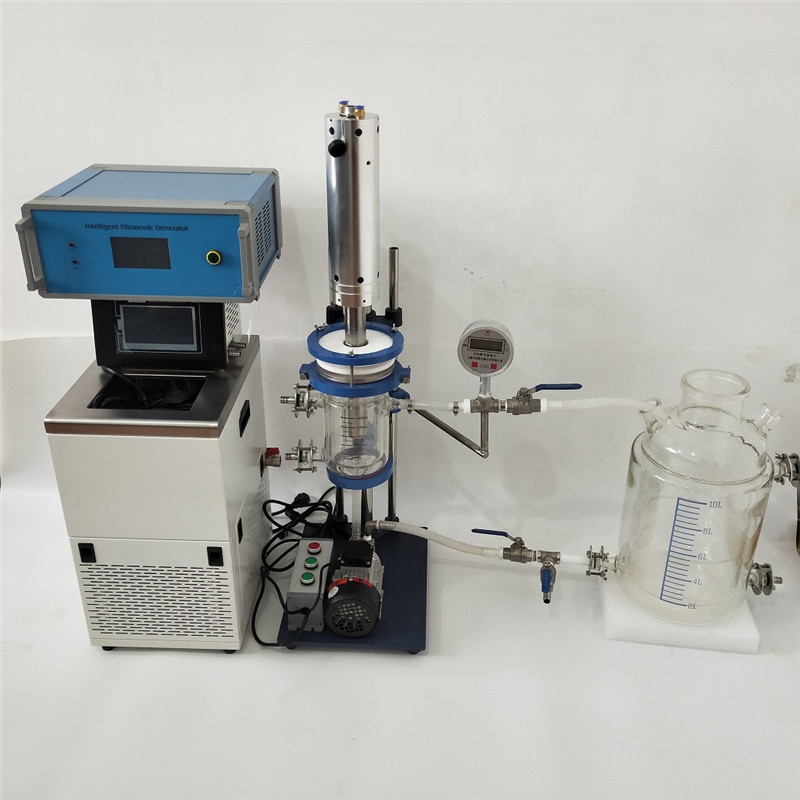

3000W ultrasonic dispersion equipment

The mixing of powders into liquids is a common step in the formulation of various products, such as paint, ink, shampoo, beverages, or polishing media. The individual particles are held together by attraction forces of various physical and chemical nature, including van der Waals forces and liquid surface tension. This effect is stronger for higher viscosity liquids, such as polymers or resins. The attraction forces must be overcome on order to deagglomerate and disperse the particles into liquid media.

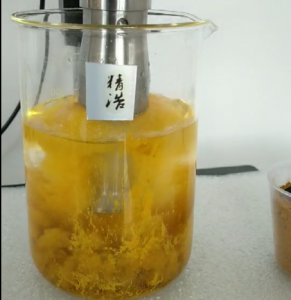

Ultrasonic cavitation in liquids causes high speed liquid jets of up to 1000km/h (approx. 600mph). Such jets press liquid at high pressure between the particles and separate them from each other. Smaller particles are accelerated with the liquid jets and collide at high speeds. This makes ultrasound an effective means for the dispersing and deagglomeration but also for the milling and fine grinding of micron-size and sub micron-size particles.

The dispersing and deagglomeration of solids into liquids is an important application of ultrasonic devices. Ultrasonic cavitation generates high shear that breaks particle agglomerates into single dispersed particles.

SPECIFICATIONS:

|

MODEL |

JH-BL5 JH-BL5L |

JH-BL10 JH-BL10L |

JH-BL20 JH-BL20L |

|

Frequency |

20Khz |

20Khz |

20Khz |

|

Power |

1.5Kw |

3.0Kw |

3.0Kw |

|

Input Voltage |

220/110V, 50/60Hz |

||

|

Processing Capacity |

5L |

10L |

20L |

|

Amplitude |

0~80μm |

0~100μm |

0~100μm |

|

Material |

Titanium alloy horn, glass tanks. |

||

|

Pump Power |

0.16Kw |

0.16Kw |

0.55Kw |

|

Pump Speed |

2760rpm |

2760rpm |

2760rpm |

|

Max.Flow Rate |

10L/Min |

10L/Min |

25L/Min |

|

Horses |

0.21Hp |

0.21Hp |

0.7Hp |

|

Chiller |

Can control 10L liquid, from -5~100℃ |

Can control 30L liquid, from -5~100℃ |

|

|

Remarks |

JH-BL5L/10L/20L,match with a chiller. |

||

APPLICATIONS:

This system is for small scale thin viscosity liquids processing, such as oil, carbon black, carbon nanotubes, graphene, coatings, new energy materials, alumina, nanoemulsions processing.