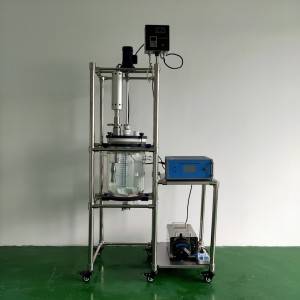

20Khz ultrasonic pigment coating paint dispersing machine

Ultrasonic dispersing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed.

When ultrasonic dispersing machines are used as homogenizers, the objective is to reduce small particles in a liquid to improve uniformity and stability. These particles (disperse phase) can be either solids or liquids. A reduction in the mean diameter of the particles increases the number of individual particles. This leads to a reduction of the average particle distance and increases the particle surface area.

Ultrasonic cavitation produces countless high and low pressure zones in the liquid. These high and low pressure zones continuously impact solid particles such as: TiO2, SiO2, ZrO2, ZnO, CeO2 during the circulation process to deagglomerate them, reduce the size of the particles, and increase the surface contact area between the particles, so disperse evenly into the solution.

SPECIFICATIONS:

| MODEL | JH-BL20 |

| Frequency | 20Khz |

| Power | 3000W |

| Input voltage | 110/220/380V, 50/60Hz |

| Agitator speed | 0~600rpm |

| Temperature display | Yes |

| Peristaltic pump speed | 60~600rpm |

| Flow rate | 415~12000ml/min |

| Pressure | 0.3Mpa |

| OLED display | Yes |