20Khz ultrasonic dispersion equipment

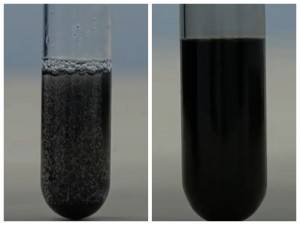

There are many types of equipment for preparing mixed solutions, such as homogenizers, mixers, and grinders. But these conventional mixing equipments often fail to achieve the ideal mixing state. It is a common problem that the particles are not fine enough and the mixed solution is easy to separate. Ultrasonic dispersion equipment can overcome these problems.

The cavitation effect of ultrasonic vibration can produce countless small bubbles in the liquid. These small bubbles are instantly formed, expanded, and collapsed. This process generates countless high and low pressure areas.Cyclic collisions between high and low pressure can break the particles, thereby reducing the particle size.

SPECIFICATIONS:

| MODEL | JH-ZS5/JH-ZS5L | JH-ZS10/JH-ZS10L |

| Frequency | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |

| Processing capacity | 5L | 10L |

| Amplitude | 10~100μm | |

| Cavitation intensity | 2~4.5 w/cm2 | |

| Material | Titanium alloy horn, 304/316 ss tank. | |

| Pump power | 1.5Kw | 1.5Kw |

| Pump speed | 2760rpm | 2760rpm |

| Max. flow rate | 160L/min | 160L/min |

| Chiller | Can control 10L liquid, from -5~100℃ | |

| Material particles | ≥300nm | ≥300nm |

| Material viscosity | ≤1200cP | ≤1200cP |

| Explosion proof | NO | |

| Remarks | JH-ZS5L/10L,match with a chiller | |

ADVANTAGES:

- The device can work continuously for 24 hours, and the life of the transducer is up to 50000 hours.

- The horn can be customized according to different industries and different working environments in order to achieve the best processing effect.

- Can be connected to PLC, making operation and information recording more convenient.

- Automatically adjust the output energy according to the change of liquid to ensure that the dispersion effect is always in the best state.

- Can handle temperature sensitive liquids.

Write your message here and send it to us