2020 wholesale price Ultrasonic Cbd Oil Processing Machine - Ultrasonic emulsifying device for biodiesel processing – JH

2020 wholesale price Ultrasonic Cbd Oil Processing Machine - Ultrasonic emulsifying device for biodiesel processing – JH Detail:

Biodiesel is a form of diesel fuel derived from plants or animals and consisting of long-chain fatty acid esters. It is typically made by chemically reacting lipids such as animal fat (tallow), soybean oil, or some other vegetable oil with an alcohol, producing a methyl, ethyl or propyl ester.

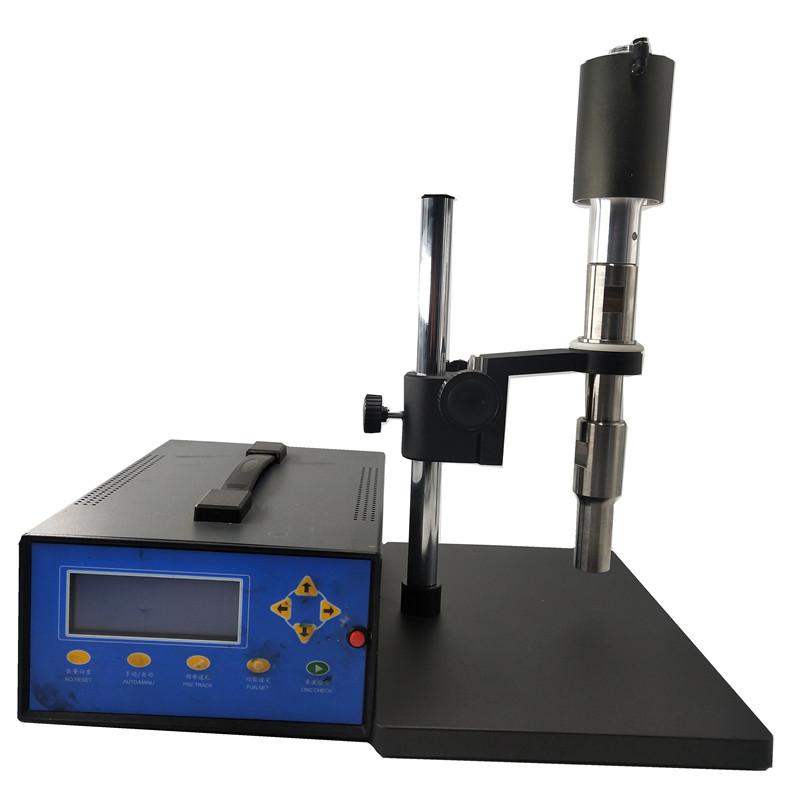

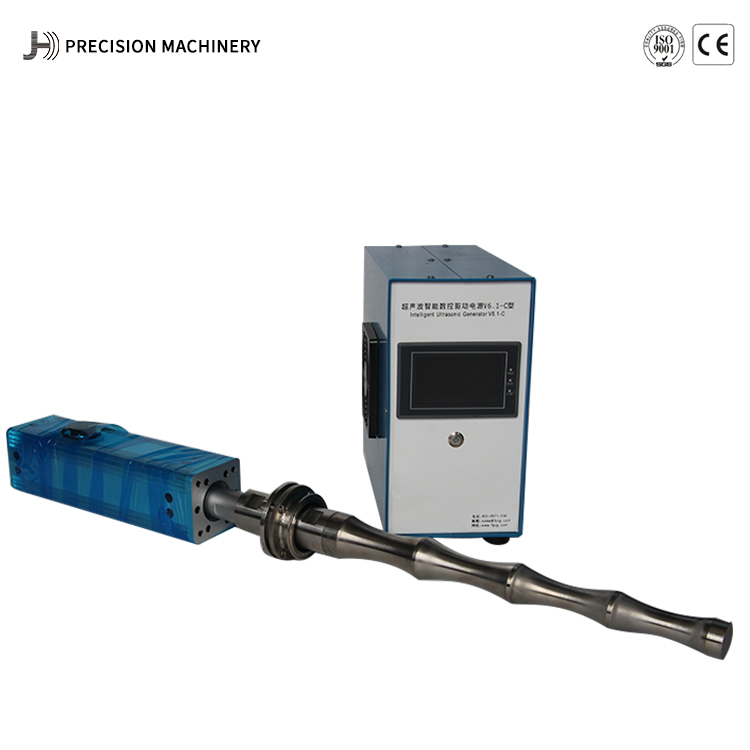

Traditional biodiesel production equipment can only be processed in batches, resulting in very low production efficiency. Due to the addition of many emulsifiers, the yield and quality of biodiesel are relatively low.Ultrasonic biodiesel emulsification equipment can realize continuous on-line processing, and the production efficiency can be increased by 200-400 times. At the same time, the ultra-high ultrasonic power can reduce the use of emulsifiers. The oil yield of biodiesel prepared in this way is as high as 95-99%. The quality of oil is also significantly improved.

SPECIFICATIONS:

| MODEL | JH-ZS30 | JH-ZS50 | JH-ZS100 | JH-ZS200 |

| Frequency | 20Khz | 20Khz | 20Khz | 20Khz |

| Power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Input voltage | 110/220/380V,50/60Hz | |||

| Processing capacity | 30L | 50L | 100L | 200L |

| Amplitude | 10~100μm | |||

| Cavitation intensity | 1~4.5w/cm2 | |||

| Temperature control | Jacket temperature control | |||

| Pump power | 3.0Kw | 3.0Kw | 3.0Kw | 3.0Kw |

| Pump speed | 0~3000rpm | 0~3000rpm | 0~3000rpm | 0~3000rpm |

| Agitator power | 1.75Kw | 1.75Kw | 2.5Kw | 3.0Kw |

| Agitator speed | 0~500rpm | 0~500rpm | 0~1000rpm | 0~1000rpm |

| Explosion proof | No, but can be customized | |||

BIODIESEL PROCESSING STEPS:

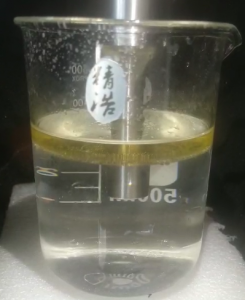

1. Mix vegetable oil or animal fat with methanol or ethanol and sodium methoxide or hydroxide.

2. Electric heating the mixed liquid to 45 ~ 65 degrees Celsius.

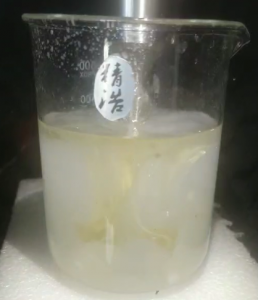

3. Ultrasonic treatment of the heated mixed liquid.

4. Use a centrifuge to separate glycerin to obtain biodiesel.

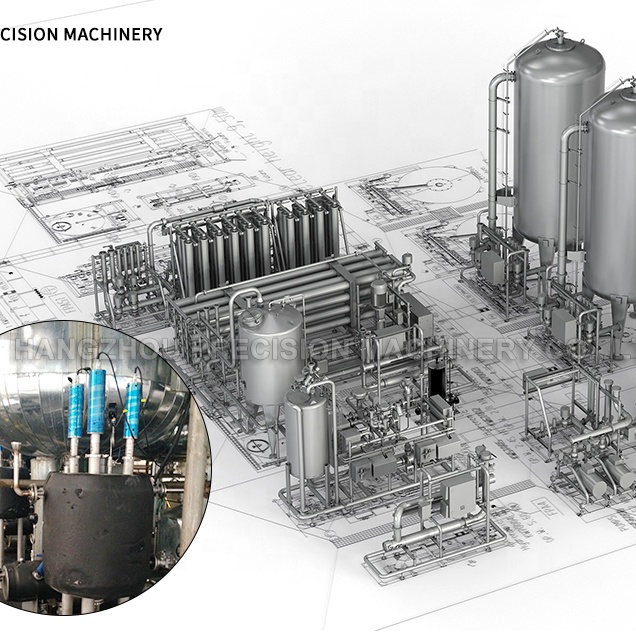

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for 2020 wholesale price Ultrasonic Cbd Oil Processing Machine - Ultrasonic emulsifying device for biodiesel processing – JH , The product will supply to all over the world, such as: Guyana, Amman, Amsterdam, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.