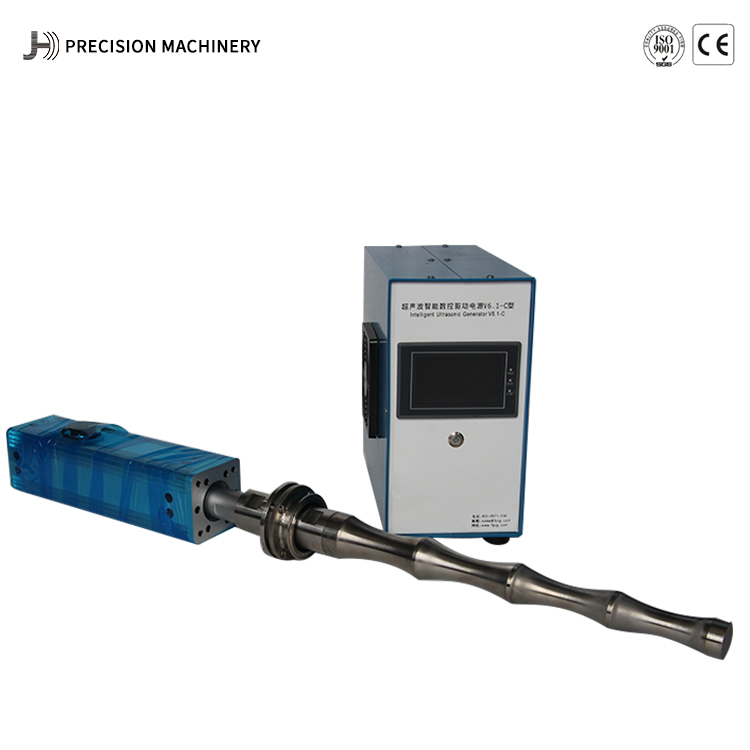

2020 China New Design Ultrasonic Device For Liquid Processing - Ultrasonic dispersion sonicator homogenizer – JH

2020 China New Design Ultrasonic Device For Liquid Processing - Ultrasonic dispersion sonicator homogenizer – JH Detail:

Ultrasonic homogenizing is a mechanical process to reduce small particles in a liquid so that they become uniformly small and evenly distributed. Sonicators work by generating intense sonic pressure waves in a liquid media. The pressure waves cause streaming in the liquid and, under the right conditions, rapid formation of micro-bubbles which grow and coalesce until they reach their resonant size, vibrate violently, and eventually collapse. This phenomenon is called cavitation. The implosion of the vapor phase bubbles generates a shock wave with sufficient energy to break covalent bonds. Shear from the imploding cavitation bubbles as well as from eddying induced by the vibrating sonic transducer disrupt cells.

SPECIFICATIONS:

| MODEL | JH1500W-20 | JH2000W-20 | JH3000W-20 |

| Frequency | 20Khz | 20Khz | 20Khz |

| Power | 1.5Kw | 2.0Kw | 3.0Kw |

| Input voltage | 110/220V, 50/60Hz | ||

| Amplitude | 30~60μm | 35~70μm | 30~100μm |

| Amplitude adjustable | 50~100% | 30~100% | |

| Connection | Snap flange or customized | ||

| Cooling | Cooling fan | ||

| Operation Method | Button operation | Touch screen operation | |

| Horn material | Titanium alloy | ||

| Temperature | ≤100℃ | ||

| Pressure | ≤0.6MPa | ||

ADVANTAGES:

1.The device can work continuously for 24 hours, and the life of the transducer is up to 50000 hours.

2.The horn can be customized according to different industries and different working environments in order to achieve the best processing effect.

3.Can be connected to PLC, making operation and information recording more convenient.

4.Automatically adjust the output energy according to the change of liquid to ensure that the dispersion effect is always in the best state.

5.Can handle temperature sensitive liquids.

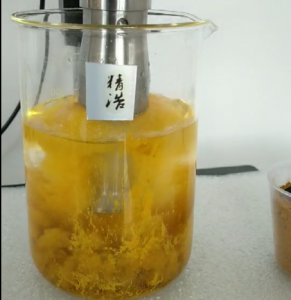

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for 2020 China New Design Ultrasonic Device For Liquid Processing - Ultrasonic dispersion sonicator homogenizer – JH , The product will supply to all over the world, such as: Morocco, Naples, Kenya, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.